At a glance

- Explore the wide-ranging applications of PEEK Engineering Plastic, from aerospace to healthcare, and witness its exceptional properties in action.

- ePol stands as your reliable source for top-quality PEEK plastic sheets and rods, ensuring professionalism and excellence in every delivery.

- Embrace the future with PEEK's sustainability and 3D printing capabilities, and explore how this exceptional material can revolutionise your industry.

In the world of advanced engineering plastics, PEEK, or Polyether Ether Ketone, stands as a shining example of innovation and versatility. PEEK plastic has been at the forefront of materials technology since its inception, thanks to its exceptional blend of properties.

PEEK Plastic Sheet and Rod: Unveiling the Marvel

Polyether Ether Ketone, commonly referred to as PEEK, is a high-performance engineering plastic renowned for its mechanical strength, temperature resistance, and chemical resilience. Its molecular structure, characterised by rigid benzene rings, flexible ether bonds, and carbonyl groups, fosters strong intermolecular forces, rendering it a material of exceptional value.

Key Properties of PEEK Plastic: The Backbone of Excellence

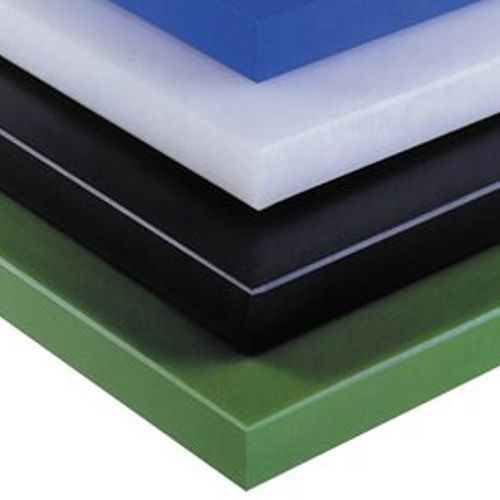

Peek plastic sheet and rod alike boast an impressive array of properties that make them indispensable in demanding applications. Here are the key attributes that set PEEK apart:

Mechanical Excellence

PEEK plastic exhibits impressive mechanical strength, withstanding high stresses and loads. Its bending and compressive strengths at elevated temperatures are remarkable, making it a top choice for components operating in demanding conditions.

Unrivalled Temperature Resistance

PEEK's ability to thrive in extreme temperatures is a game-changer. It can endure prolonged exposure to temperatures up to 250°C and, in short bursts, can even withstand 300°C without breaking a sweat. This remarkable heat tolerance positions PEEK as a material of choice for applications where other plastics falter.

Chemical Resistance

PEEK plastic’s resistance to various chemicals is akin to that of nickel steel. It remains unscathed by most chemicals, even at elevated temperatures. Only concentrated sulfuric acid poses a challenge to its chemical resilience.

Low Smoke, High Safety

When exposed to flames, PEEK plastic exhibits minimal smoke and toxic gas emissions. This flame retardant property ensures a safer environment in case of fire.

ePol: Your Australian Supplier of PEEK Plastic Sheet and Rod

For those seeking a reliable source of PEEK plastic sheet and rod in Australia, look no further than ePol. As a trusted supplier, ePol offers the highest quality PEEK plastic, available in both sheet and rod forms. What sets ePol apart is its commitment to quality and customer satisfaction. ePol's PEEK is not only top-notch in terms of performance but is also FDA-approved, guaranteeing its suitability for a wide range of applications, including those in the food and medical industries.

With ePol, you gain access to live online pricing and inventory, allowing you to plan your manufacturing pipeline with ease. Plus, their commitment to customer service ensures worry-free deliveries, complete with tracking links and updates on stock arrivals. Whether you're ordering as a trade customer or an individual, ePol's convenient checkout options make the entire process effortless.

PEEK in Healthcare and Medical Applications

Use in Medical Instruments and Equipment

PEEK plastic’s exceptional properties make it a preferred choice for manufacturing various medical instruments and equipment. Its outstanding mechanical strength, combined with good stress resistance and hydrolytic stability, is a boon in the demanding world of healthcare. Medical professionals rely on PEEK for instruments that require high-temperature steam sterilisation, where the plastic excels in maintaining performance and durability.

Applications in Orthopedics and Dentistry

In orthopedics, PEEK is a go-to material for implants and components that require resilience under the stresses of daily life. Its compatibility with the human body, in terms of weight, toxicity, and corrosion resistance, makes it a standout choice.

Dentistry also embraces PEEK for its handle materials and sterile boxes for root canal files, where it can withstand autoclave sterilisation cycles with ease. The material's ability to maintain mechanical strength and stress-cracking resistance in the presence of hot water, steam, solvents, and chemicals makes it invaluable in dental applications.

PEEK's Role in Trauma Fixation and Prosthetics

PEEK-based implants offer an attractive alternative to metal implants. They provide stability, biocompatibility, and a reduced risk of complications.

PEEK's ability to closely mimic the mechanical properties of human bone is a game-changer in trauma fixation, ensuring effective healing and recovery.

Food Processing Industry

Employment in Food Processing Machinery Components

PEEK's chemical resistance, high-temperature tolerance, and robust mechanical properties make it an ideal candidate for components in food processing machinery. Whether it's manufacturing parts for machines involved in food production, packaging, or quality control, PEEK ensures that operations run smoothly and with minimal risk of contamination.

The Importance of FDA Approval for Food-Grade Applications

In the food processing industry, safety is non-negotiable. That's why PEEK plastic rod and sheet FDA approval is a game-changer. This certification signifies that PEEK meets the rigorous standards set for materials that come into contact with food. From conveyor belts to seals and gaskets, PEEK plastic compliance with food-grade requirements ensures that the end products are safe for consumption.

PEEK's Chemical Resistance and Suitability for Food Contact

Another noteworthy trait of PEEK is its exceptional chemical resistance, which includes resistance to water and high-pressure water vapour. Even when continuously soaked in water at 100°C for extended periods, PEEK plastics strength remains virtually unchanged. This quality is a boon in the food processing industry, where exposure to moisture and cleaning agents is common.

In addition to its resistance, the plastics suitability for food contact is a result of its low water absorption rate. This property makes it a dependable choice for applications involving pressurised hot water or steam at temperatures as high as 300°C.

PEEK in Electronic and Electrical Fields

Applications in Electronic and Electrical Components

PEEK plastic's excellent electrical insulation properties make it an ideal choice for various electronic components. It provides parts with long-term operating reliability, even when subjected to widely fluctuating ranges of temperature, pressure, and frequency. This makes it indispensable in applications where precision and consistency are critical.

One notable application is the production of coaxial connector jacks used in hands-free telephone kits. The plastics insulation properties ensure the reliable transmission of signals, a necessity in modern communication technology.

Supporting the Semiconductor Industry

PEEK plastic’s inherent purity, combined with outstanding mechanical and chemical stability, minimises contamination during the handling of delicate silicon wafers. This level of cleanliness is essential to ensure the quality of semiconductor devices.

High-Temperature Resilience

The engineering plastic’s remarkable thermal properties enable it to withstand the elevated temperatures associated with soldering processes. This resilience is crucial in the production of electronic components, where precise manufacturing and assembly are essential for performance and reliability.

Empowering Energy Solutions with PEEK

Oil Exploration and Production

In the oil exploration and production industry, PEEK plastic is a valuable material for manufacturing probes with special geometries and connectors for oil extraction. Its ability to withstand high pressures and temperatures up to 260°C ensures that it can perform reliably in the harshest of environments.

Reducing Wear and Noise

PEEK plastic is also making an impact by replacing stainless steel in impeller wheels for regenerative pumps. This transition significantly reduces wear and noise levels, leading to longer service life and improved efficiency.

Sustainability and 3D Printing with PEEK plastics

Recyclability of PEEK and Environmental Benefits

PEEK plastic isn't just about performance; it also carries significant environmental advantages. PEEK is fully recyclable, making it a sustainable choice for those concerned about the planet. Its recyclability not only reduces waste but also conserves valuable resources. This commitment to eco-friendliness aligns seamlessly with the growing emphasis on sustainability across industries.

Feasibility of 3D Printing with PEEK

The world of manufacturing is evolving, and 3D printing is at the forefront of this revolution. PEEK plastic’s adaptability to 3D printing processes presents exciting opportunities. But what makes 3D printing with PEEK plastic so appealing?

Advantages of 3D Printing PEEK

3D printing PEEK offers a plethora of benefits:

Enhanced Performance:

PEEK plastic inherent properties are further enhanced through 3D printing. The process allows for precise customisation, resulting in parts that meet exact specifications and offer superior performance.

Design Freedom:

3D printing with PEEK unleashes design freedom. Complex geometries, intricate structures, and lightweight yet robust components become achievable. This newfound freedom sparks innovation across industries.

Common Questions About PEEK

Is PEEK plastic Food Grade?

Yes, PEEK plastic is indeed food grade. Its FDA approval solidifies its suitability for use in food-related applications. When it comes to safety and compliance with food-grade standards, PEEK stands as a reliable choice.

Is PEEK plastic Recyclable?

Absolutely. PEEK plastic is fully recyclable, contributing to sustainability efforts. Its recyclability not only reduces environmental impact but also underscores its commitment to a greener future.

Can PEEK plastic be 3D printed?

Certainly, PEEK plastic can be 3D printed with remarkable advantages. 3D printing PEEK offers enhanced performance and unparalleled design freedom, opening doors to innovative possibilities across various industries.

Is PEEK used in the medical industry?

Indeed, PEEK plays a pivotal role in the medical industry. Its applications range from medical instruments and trauma fixation to dental implants and prosthetics. PEEK's biocompatibility and exceptional performance make it a trusted material in healthcare.

Discover the world of PEEK Engineering Plastic sheets and rods with ePol. Explore our wide range of PEEK plastic sheets and rods, carefully sourced and delivered with excellence. Contact us today to witness the difference that reliability and professionalism can make in your industry.

In summary, PEEK Engineering Plastic emerges as a remarkable material, offering a unique blend of properties that fuel its versatile applications across a spectrum of industries. Its impressive heat tolerance, mechanical prowess, and chemical resistance make it a reliable choice, while its environmental sustainability and adaptability to 3D printing showcase its forward-looking nature.

From aerospace to healthcare, food processing to electronics, PEEK plastics play a pivotal role in elevating performance standards and enabling innovation. As you embark on your journey to explore the vast potential of PEEK, look no further than ePol, your trusted Australian supplier, known for its unwavering reliability and professionalism.