At a glance

- Cast nylon's exceptional properties, including wear resistance and impact strength, make it a go-to material in construction.

- A wide range of construction components benefit from cast nylon, from sheaves and pulleys to gears and outrigger pads.

- Nylon Insights: Gain insights into different types of nylon, their applications, and their environmental impact in the construction industry.

In the dynamic world of construction, innovation and adaptability reign supreme. Cast nylon, an unsung hero in the engineering plastics realm, has silently but significantly contributed to the construction sector's evolution.

Our journey has been one of collaboration with industry-leading technical and design experts, resulting in the development of enduring plastic alternatives that have disrupted traditional construction materials.

In this article, we'll explore how cast nylon's exceptional attributes are revolutionising the construction industry, reshaping how structures and machinery are crafted, and delivering tangible benefits to businesses.

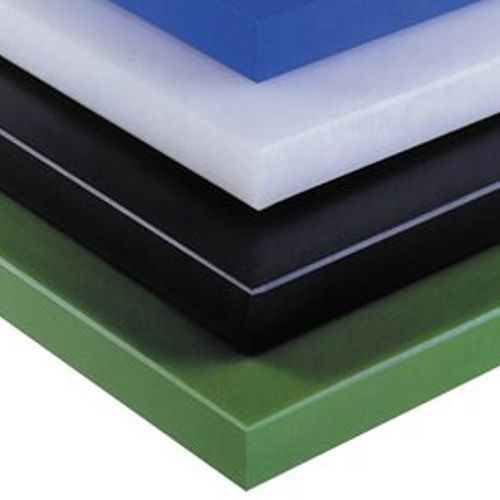

The Versatility of Cast Nylon Sheets

At the core of cast nylon's transformative role in construction lies its incredible versatility. Cast nylon sheets have become indispensable across a spectrum of applications, thanks to their remarkable properties. They have:

Unmatched Resistance to Wear and Abrasion

In the demanding world of construction, where equipment faces relentless wear and tear, cast nylon emerges as a game-changer. It resists wear and abrasion, outlasting conventional metals even under the most punishing conditions. This translates to extended component lifespans and fewer replacements.

Outstanding Impact Strength

In construction's high-stakes arena, impact resistance is paramount. Cast nylon steps up to the plate with its superior impact strength, making it the preferred choice for machinery components and structural elements. This heightened resistance reduces the risk of damage, keeping projects on track.

Self-Lubrication: A Maintenance Game-Changer

Cast nylon's self-lubricating properties bring a breath of fresh air to the construction industry. In environments where friction runs high, this feature slashes the need for constant lubrication, cutting down on maintenance expenses and averting equipment breakdowns.

Electrical Insulation

Electrical systems form the backbone of many construction projects. Cast nylon's insulating properties make it a natural fit for electrical components and enclosures, ensuring safety and reliability on the job site.

Immunity to Corrosion and Chemicals

Exposure to the elements and harsh chemicals is par for the course in construction. Cast nylon's innate resistance to corrosion and chemicals fortifies components, allowing them to thrive in challenging environments and reducing ongoing maintenance.

Low Friction: Smoother Operations

In applications where low friction is pivotal – think bearings and gears – cast nylon's low coefficient of friction ensures seamless operation, boosts energy efficiency, and prolongs the life of critical components.

High Visibility and Safety

Safety is paramount in construction. Cast nylon's high visibility and array of colour options enhance component identification, contributing to heightened safety on construction sites.

Cast Nylon's Role in Construction

The construction industry relies on an array of tools and machines, and timely completion of projects is vital for profitability. That's why many construction companies and equipment manufacturers are making the switch to cast nylon components.

Diverse Applications in Construction

The potential applications for cast nylon are nearly boundless. Here's a glimpse of some essential components and parts in the construction sector that are benefiting immensely from cast nylon's exceptional properties:

- Sheaves & Pulleys

- Bushings

- Spacers

- Pipe clamps

- Sprockets

- Bearing blocks

- Bearing housings

- Chain guides

- Gears

- Wear strips

- Wear pads

- Scrapers

- Bespoke components

- Boom pads

- Slew rings

- Lever

- Skate rollers

- Stoppers

- Outrigger pads

Understanding the Nylon Family

Nylon, a versatile synthetic polymer, boasts a diverse family, each with unique properties. Here's a quick tour of five nylon types and their practical applications:

Nylon 1,6

Derived from adiponitrile, formaldehyde, and water, Nylon 1,6 exhibits high moisture absorbance but is not a typical choice for fabrics. Its applications extend to various industrial uses.

Nylon 4,6

Nylon 4,6 shines in applications requiring elevated operating temperatures, such as engine components (e.g., transmissions, brakes, and air cooling systems). Its resistance to heat and chemicals makes it a go-to material in specific industries.

Nylon 510

Nylon 510, known for superior properties, finds its niche in industrial and scientific applications due to its elevated production costs.

Nylon 6

Nylon 6, celebrated for its robustness, high tensile strength, and resistance to abrasion and chemicals, finds applications in diverse industries, including automotive, electronics, aviation, clothing, and medicine.

Nylon 6,6

Nylon 6,6, a more crystalline sibling of nylon 6, impresses with enhanced mechanical properties owing to its ordered molecular structure. It delivers strengths in key areas like wear pads, guide wheels, and slide bearings.

Sustainability and Environmental Insights

Sustainability is gaining momentum in construction, and while nylon production has its environmental impacts, it's vital to highlight the material's recyclability. Innovations like Econyl, crafted from recycled nylon sources like fishing lines and post-consumer waste, champion more eco-conscious practices.

Quality Assurance and Safety

Ensuring nylon quality involves a meticulous examination of mechanical, thermal, electrical, and physical properties. Nylon, in general, is considered safe; however, individuals sensitive to petroleum-based materials should exercise caution.

Nylon in Plastic Injection Molding

In the realm of plastic injection moulding, Nylon 6 and Nylon 66 take center stage due to their remarkable attributes, including strength, heat resistance, wear resistance, lubricity, and chemical resilience. These materials play pivotal roles across industries, including construction.

Nylon Sheets: Pioneering Industrial Manufacturing

Nylon, in all its forms, finds applications in industrial manufacturing. Nylon 6 and Nylon 66 emerge as the stars of the show. These materials offer strength, abrasion resistance, and unparalleled versatility. They permeate various sectors, from food and agriculture to transportation and energy.

CAST NYLON | ENGINEERING PLASTICS ONLINE

When it comes to mechanical machine parts, cast nylon stands as an undisputed champion. Renowned for its toughness, exceptional wear resistance, impressive tensile strength, and natural lubricity, it's no wonder cast nylon is the top choice for a wide range of applications.

You might have heard it by various names like Nylacast®, Sustamid®, Tecast®, Ertalon®, Austlon®, Nylatron®, Zellamid®, or Tecamid®, but the performance remains unmatched. At ePol, we offer cast nylon in both rod and sheet forms, ensuring you have access to the right materials for your specific needs.

CAST NYLON IS USED FOR: From rollers and wheels to bearings, guides, and spacers, cast nylon's versatility shines through in a multitude of applications. It finds its place in pallets, gears, slide plates, sieves, gaskets, seals, rack gears, star wheels, and liners, showcasing its adaptability across various industries.

PERFORMANCE CHARACTERISTICS

What sets cast nylon apart are its exceptional characteristics. With very low levels of internal stress and a high degree of crystallinity, it boasts toughness even at high levels of hardness. Add to that its remarkable wear resistance, good abrasion resistance, excellent damping properties, and ease of processing, and you've got a material that consistently delivers top-tier performance.

At ePol, we understand the significance of cast nylon in engineering and construction, and we're here to provide you with the highest quality materials and support for your projects. Choose cast nylon for reliability and durability in your mechanical machine parts, and experience engineering plastics at their finest.

Contact us today!

Ready to harness the power of cast nylon in your construction projects? Contact ePol today, and let's build a stronger, more efficient future together. Explore our range of cast nylon solutions and elevate your construction game!

In conclusion, cast nylon stands as an unsung hero in the construction industry, bringing a plethora of advantages that elevate structural integrity, operational efficiency, and sustainability. Its adaptability, exceptional properties, and versatility make it a priceless asset for crafting diverse construction components.

As the construction sector continues its journey of transformation, cast nylon remains at the forefront of innovation, reshaping machinery design and construction practices. By choosing cast nylon, the construction industry not only enhances project outcomes but also contributes to a greener future for the built environment