At a glance

- PEEK's exceptional compatibility with the human body ensures safe medical implantation.

- Tailor-made solutions with PEEK, thanks to 3-D printing and injection moulding.

- From spinal implants to cardiovascular innovations, PEEK is reshaping medical device manufacturing.

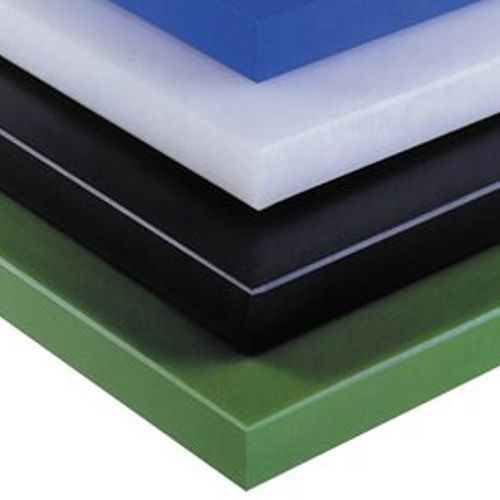

In the ever-evolving landscape of medical device manufacturing, one material has stood out for its remarkable versatility and impact: Polyether ether ketone (PEEK). This high-performance polymer, available in various forms, such as PEEK plastic sheets and rods, has brought about a paradigm shift in the medical industry.

PEEK Plastic's Advantages in Medical Manufacturing

Traditionally, metal components were the norm for medical implants. However, PEEK plastic has rapidly gained traction for several compelling reasons:

Biocompatibility: PEEK's Compatibility with the Human Body

One of PEEK's defining features is its exceptional biocompatibility. When it comes to medical implants and devices, ensuring they do not trigger adverse immune responses is paramount. PEEK plastic excels in this regard, making it a safe choice for implantation.

Additionally, PEEK's resistance to heat and medical sterilisation chemicals makes it a versatile material for crafting reusable medical tools, further enhancing its significance in the medical field.

Mimicking Nature: PEEK plastic's Elasticity and Lightweight Nature

PEEK plastic’s elasticity closely mimics that of human bone, allowing for joints and implants made from this material to bear weight and move naturally. This property not only enhances the performance of implants but also contributes to patient comfort and recovery.

Furthermore, PEEK is notably lightweight when compared to most metals. This weight advantage simplifies patient recovery and provides an overall more comfortable experience.

PEEK's Role in Crafting Complex Geometries

Many medical devices require intricate designs with precise tolerances. PEEK plastic excels in such scenarios:

Machining Versatility

PEEK plastic and rod sheets can withstand extended machining processes, preserving the integrity of complex parts. This resistance to erosion is vital in maintaining the precision of medical components.

Injection Moulding

Injection moulding is a common method for producing medical components at scale. PEEK plastic's high melting point allows for faster production runs, making it a highly suitable material for large-scale manufacturing.

Customised Solutions with PEEK plastic

Polyether ether ketone (PEEK) has emerged as a transformative material in the medical industry, offering remarkable benefits for precision and customised solutions. In orthopedic procedures like osteotomies, where personalised implants are critical, PEEK's compatibility with injection moulding and 3-D printing plays a pivotal role.

With the power of personalisation, PEEK rod sheets enable the creation of implants tailored to individual patients, matching their unique anatomy precisely. These customised implants lead to improved patient outcomes by promoting better fit, stability, and functionality while reducing the risk of complications and the need for revision surgeries.

PEEK plastics versatility allows it to be moulded into complex geometries, ensuring a perfect fit and functionality for intricate orthopedic devices. Additionally, PEEK's lightweight nature contributes to shorter recovery times, allowing patients to regain mobility and functionality sooner after surgery.

PEEK's Rapid Ascendancy in the Medical Field

PEEK has quickly become indispensable in various medical disciplines. Let's explore its key applications:

Spinal Implants

PEEK plastics’ optimal modulus, which closely resembles that of cortical bone, and its radiolucency make it a top choice for spinal implant procedures. It is particularly beneficial in treating conditions like degenerative disc disease, spinal stenosis, degenerative scoliosis, and degenerative spondylolisthesis.

Trauma Fixation

PEEK is gaining prominence in trauma fixation due to its superior fatigue strength. Whether used in bone plates, screws, nails, anchors, or other components, PEEK extends the lifespan of implanted materials, benefiting patients in the long run.

Orthopaedic Procedures

Orthopedic surgeries, including knee and hip arthroplasty, benefit from PEEK plastic sheet’s bone-like modulus. This property allows implants to bear weight and move naturally, contributing to patient comfort and better joint function.

Cardiovascular Innovation

In cardiovascular medicine, PEEK plays a crucial role in Less Invasive Ventricular Enhancement (LIVE) procedures. LIVE offers a safer alternative to traditional methods of repairing heart damage following a myocardial infarction. PEEK anchors and tethers stabilise the left ventricle, ensuring its functionality and patient well-being.

Dental Advancements

PEEK is highly regarded in dentistry, particularly for removable partial dentures. Patients benefit from PEEK's durability, comfort, aesthetics, and its ability to seamlessly blend with natural teeth.

Radiolucency

PEEK plastics radiolucency allows for clear imaging, ensuring that surgeons can monitor patient progress without interference from imaging artifacts. This is especially valuable in procedures where precision is paramount.

Trusted PEEK plastic supplier

Looking for reliable and high-quality PEEK plastic supplies in Australia? Choose ePol! Our commitment to excellence and a wide range of products make us your trusted partner. Explore our offerings today and experience the difference with ePol.

In the dynamic landscape of medical device manufacturing, PEEK plastic, available in the forms of sheets and rods, has emerged as a game-changer. Its exceptional biocompatibility, ability to mimic human bone elasticity, and versatility in crafting complex geometries have paved the way for innovative medical solutions.

From spinal implants to trauma fixation, orthopaedics to cardiovascular procedures, and even dentistry, PEEK's rapid ascent in the medical field is a testament to its precision and limitless possibilities. As medical technology continues to advance, PEEK will undoubtedly play a pivotal role in shaping the future of healthcare.