At a glance

- Discover the remarkable world of cast nylon, an engineering plastic that revolutionises diverse industries.

- Cast nylon's low-friction properties and exceptional resilience make it a superior alternative to metal components.

- Unveil its manufacturing process, properties, and the common types of cast nylon.

- Explore how it finds applications in textiles, automotive, electrical, and more.

- Delve into its significance in modern industrial processes and the crucial role it plays in shaping the future of engineering plastics in Australia.

In the dynamic world of engineering plastics in Australia, cast nylon stands out as a remarkably adaptable and durable material. With a broad spectrum of applications across various industries, cast nylon is a true workhorse. In this article, we will take a deep dive into the world of cast nylon, exploring its exceptional properties and its vital role in industries such as manufacturing, automotive, agriculture, and construction.

Understanding Cast Nylon

Before we delve into its applications, let's understand what cast nylon is. Cast nylon, also known as polyamide (PA), is an engineering-grade thermoplastic. It's characterised by its high temperature, chemical and electrical resistance, thanks to its crystalline structure.

This material is renowned for its durability, versatility, high tensile strength, and resistance to fatigue. Its excellent abrasion and friction behaviour, along with flame retardant capabilities, make it an invaluable choice across industries.

The Versatility of Cast Nylon

Cast nylon exhibits both amorphous and crystalline microstructures when cooled, granting it elasticity, rigidity, and stiffness. These versatile materials can also be customised by adding various additives to achieve specific material and chemical properties, making them suitable for a wide range of commercial applications.

How Cast Nylon is made?

Cast nylon rods and sheets are produced through polymerisation and polycondensation processes. Polymerisation involves reacting amine monomers with carboxylic acid, while polycondensation comprises the reaction of diamine with dicarboxylic acid.

Nylons produced through polycondensation tend to be more biodegradable, and they can even be created from biomass, enhancing material biodegradability. This highlights the adaptability of cast nylon in aligning with sustainable practices.

Properties and Mechanical Specifications

The semi-crystalline microstructure of cast nylon grants it impressive stiffness, strength, and good chemical resistance. Cast nylon can withstand heat and is an ideal choice for applications involving friction. As a thermoplastic, it can be reheated, moulded, and cooled multiple times.

However, it's essential to consider that cast nylon absorbs moisture from its surroundings, affecting dimensional stability. Preconditioning can help mitigate the impact of moisture absorption. It's also worth noting that cast nylon is not inherently UV resistant, but stabilisers can be added to reduce UV damage.

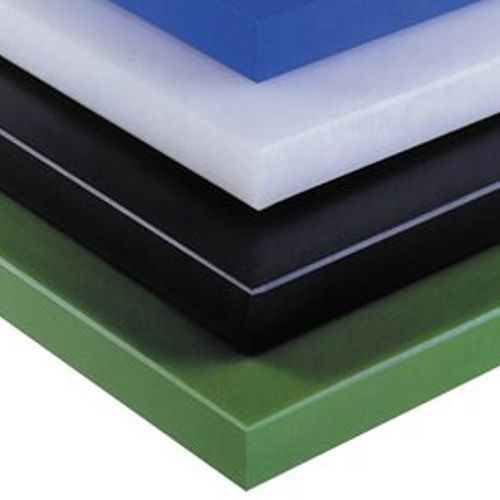

Common Types of Cast Nylon

Cast nylon types are identified by numbers, such as Nylon 6 and Nylon 66. Cast nylon can also be reinforced with additives like glass or combined with other engineering plastics to enhance performance and material characteristics.

The most common types of cast nylon include:

Nylon 6

Highly elastic fibres are used in textiles and industrial applications like apparel, ropes, and cords. These fibres have outstanding abrasion resistance and result in reliable final part dimensions.

Nylon 66

A more crystalline material that provides stiffness, tensile modulus, and flexural modulus. It's ideal for applications requiring strength, stiffness, and chemical resistance, such as carpets, airbags, and luggage.

PA 12 (Nylon 12)

Known for toughness, tensile strength, impact strength, and flexibility. PA 12 is used in injection moulding and additive manufacturing for creating functional parts and prototypes.

The Benefits of Using Cast Nylon in Various Industries

The benefits of using cast nylon in these diverse industries are plentiful. Cast nylon exhibits excellent abrasion and wear resistance, a low coefficient of friction, high tensile and compressive strength, and is incredibly lightweight, weighing only about 1/7th of conventional materials. This lightweight property makes it an excellent choice for industries where weight reduction is a priority.

What makes cast nylon even more valuable is its ease of machining. Whether for intricate parts in manufacturing or custom components in automotive, cast nylon can be shaped with precision through various methods.

Cast Nylon in Manufacturing

In the manufacturing sector, cast nylon finds extensive use. It can be moulded into various forms, including sheets, tubes, pipes, screws, bolts, and more. Custom-cast nylon is particularly prized for applications like crane pads and industrial hammer heads, where toughness and resilience are essential.

What sets cast nylon apart in manufacturing is its versatility. It can be melted into filaments for 3D printing, spun into fibres for fabrics, converted into films for packaging, and used as sheet stock for CNC machine manufacturing. This material is also a common choice in injection moulding, where it plays a crucial role in creating a wide array of components.

Cast Nylon in the Automotive Industry

The automotive sector benefits immensely from cast nylon. This engineering plastic is favoured for its lightweight nature and outstanding strength. It is used in various automotive components, from air intake manifolds to engine covers.

Air intake manifolds made from cast nylon are known for their heat resistance and light weight. They contribute to improved engine performance and fuel efficiency. Additionally, cast nylon components like fasteners and clips are essential in vehicle assembly, providing both durability and weight reduction.

Cast Nylon in Agriculture and Construction

In agriculture and construction, where ruggedness and reliability are paramount, cast nylon has found its place. This material is often used in the production of bushings, gears, and other components critical to the operation of heavy machinery. Its low coefficient of friction makes it ideal for parts that require smooth and efficient movement.

The versatility of cast nylon also shines through in conveyor systems. Nylon conveyor belts are known for their durability and low friction, making them indispensable in manufacturing, food processing, and logistics. Whether it's moving agricultural products, construction materials, or industrial goods, cast nylon ensures smooth and reliable transport.

The Uniqueness of Cast Nylon

What sets cast nylon apart from other materials is its ability to be combined with additives and stabilisers. This enables industries to fine-tune material properties to suit specific requirements. Whether it's enhancing heat resistance, improving chemical resistance, or achieving specific levels of electrical conductivity, cast nylon can be tailored to meet a wide range of needs.

Additionally, cast nylon can be shaped into various forms, including filaments, fibres, sheets, and films. This makes it compatible with a variety of manufacturing processes, such as injection moulding, CNC machining, and 3D printing, making it a versatile choice for prototyping and production.

Cast nylon, with its exceptional properties and versatility, has firmly established itself as a cornerstone of various industries in Australia. Contact ePol, your trusted supplier of cast nylon across Australia. From manufacturing to automotive, agriculture to construction, its applications are wide-ranging and indispensable. The adaptability of cast nylon, combined with its exceptional durability and strength, positions it as a vital material in modern industrial processes.

Its unique characteristics make it a preferred choice for those seeking durable, lightweight, and versatile materials in their industrial applications. Whether you are in need of robust machine parts or high-performance automotive components, cast nylon stands ready to meet your requirements, ensuring that industries across the board continue to benefit from this remarkable engineering plastic.