At a glance

- Material Insights: Explore the differences between wax-filled and oil-filled cast nylon, two specialised engineering plastics, and understand their unique advantages and applications.

- ePol's Commitment: Learn about ePol, Australia's premier engineering plastics supplier, and how their competitive pricing, live stock availability, and nationwide free delivery make them an invaluable partner for your industrial needs.

- Informed Decision-Making: Discover the essential factors to consider when choosing between wax-filled and oil-filled cast nylon for your specific application, ensuring you make informed decisions for your projects.

When it comes to selecting the right materials for your industrial applications, understanding the nuances of engineering plastics is crucial. In this comprehensive guide, we will explore the differences between two remarkable variations of cast nylon engineering plastics: oil-filled cast nylon and wax-filled cast nylon.

We aim to provide a deep insight into these materials, focusing on their applications, benefits, and the critical considerations that can guide your choice.

Engineering Plastics Supplier: Your Gateway to Advanced Materials

Before we delve into the specifics of oil-filled and wax-filled cast nylon, it's important to establish the importance of partnering with a reliable engineering plastics supplier.

The expertise and support of a trusted supplier can make all the difference in your material selection process. They can guide you in making informed decisions that align with your project requirements and industry standards.

Cast Nylon: The Versatile Engineering Plastic

Cast nylon, in its various forms, is renowned for its exceptional properties that cater to a wide range of applications. It offers high strength, excellent wear resistance, and self-lubricating characteristics, making it a popular choice in industries such as manufacturing, construction, and aerospace. However, the specific infusion of oil or wax into cast nylon can greatly impact its performance and suitability for distinct use cases.

Exploring Oil-Filled Cast Nylon

Oil-filled cast nylon, as the name suggests, is cast nylon infused with oil. This unique combination offers several advantages:

Applications of Oil-Filled Cast Nylon

Bearings and Bushings: Oil-filled cast nylon's self-lubricating properties make it an ideal choice for applications that require reduced friction and extended component life.

Gears and Rollers

It excels in scenarios where low noise and minimal maintenance are essential, like in the textile and food processing industries.

Hydraulic Components

Oil-filled cast nylon is often used in hydraulic components due to its low water absorption and resistance to hydraulic oils.

Benefits of Oil-Filled Cast Nylon

Superior Lubrication: The infused oil provides continuous lubrication, reducing wear and minimising the need for additional maintenance.

Low Coefficient of Friction: Its low friction characteristics enhance efficiency and reduce energy consumption.

Excellent Dimensional Stability: Oil-filled cast nylon maintains its shape and size, ensuring long-term performance reliability.

Considerations for Oil-Filled Cast Nylon

Cost: While it offers outstanding performance, oil-filled cast nylon can be more expensive than its wax-filled counterpart.

Compatibility: Ensure compatibility with the operating environment and chemicals involved in your application.

Exploring Wax-Filled Cast Nylon

Wax-filled cast nylon is another intriguing variant of cast nylon that offers its own set of unique features.

Applications of Wax-Filled Cast Nylon

Conveyor Systems: Its low friction characteristics make it ideal for conveyor belt components.

Wear Pads: In applications requiring resistance to wear and abrasion, such as heavy machinery, wax-filled cast nylon shines.

Benefits of Wax-Filled Cast Nylon

Food-Grade Compliance: This material is safe for use in food-related industries, meeting stringent health and safety standards.

Reduced Maintenance: Its self-lubricating properties mean less downtime for maintenance.

Cost-Effectiveness: Wax-filled cast nylon can be a cost-effective alternative, depending on your specific needs.

Considerations for Wax-Filled Cast Nylon

Operating Temperature: Be mindful of the operating temperature range, as it may not be suitable for extremely high-temperature applications.

Friction: While it has low friction properties, they may not be as low as those of oil-filled cast nylon.

Making an Informed Choice

Selecting the right cast nylon material for your application is a pivotal decision. Here are some factors to consider:

Operational Requirements

Analyse the specific needs of your project, including load-bearing capacity, wear resistance, and temperature constraints.

Budget Constraints

Evaluate your budget and see which option aligns with your financial considerations.

Environmental Factors

Consider the operating environment, including exposure to chemicals, moisture, and temperature fluctuations.

Regulatory Compliance

If your industry demands compliance with specific regulations (e.g., FDA), ensure that your choice meets those standards.

Why Choose ePol for Wax-Filled Cast Nylon and Oil-Filled cast nylon?

At ePol, we take pride in offering Australia's best range of quality engineering plastics, including wax-filled cast nylon. When you choose ePol, you benefit from:

Competitive Prices

We provide competitive pricing for all our engineering plastics, ensuring you get the best value for your investment.

Live Online Pricing and Inventory

Plan your manufacturing pipeline effectively with real-time pricing and inventory information.

Nationwide Free Shipping

Enjoy free shipping on orders over $150 (excluding GST) across Australia, ensuring cost-efficiency for your business.

Worry-Free Deliveries

We provide tracking link emails upon dispatch and have dedicated logistics brokers monitoring all consignments until delivery, giving you peace of mind.

Comprehensive Back Order System

Stay updated on stock arrivals through our back order system, empowering you to make informed decisions.

Convenient Checkout Options

We offer flexible payment options, including credit card payments and excellent trading terms, making your orders effortless.

WAX-FILLED CAST NYLON ROD

Wax-filled cast nylon rods are a versatile and reliable choice for a wide range of industrial applications. This specialised grade of cast nylon is engineered to excel in scenarios where repetitive movement in low-speed conditions under high loads is the norm.

Key Features of Wax-Filled Cast Nylon Rods

Improved Wear Resistance: Wax-filled cast nylon is designed to withstand wear and tear, making it ideal for components that experience constant friction.

Self-Lubricating: The self-lubricating properties of wax-filled cast nylon reduce the need for additional lubrication and maintenance.

Low-Speed Durability: These rods are well-suited for applications that operate at low speeds while handling heavy loads, ensuring longevity and reliability.

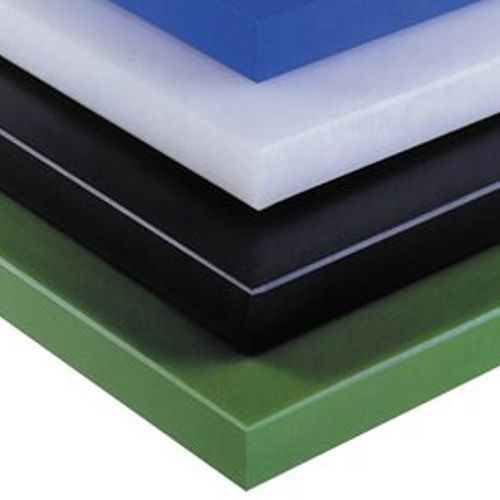

WAX-FILLED CAST NYLON SHEET

Wax-filled cast nylon sheets are a reliable choice for applications that require improved wear properties, particularly in scenarios with repetitive movement at low speeds under high loads.

Key Features of Wax-Filled Cast Nylon Sheets

Superior Wear Resistance: Wax-filled cast nylon sheets are engineered to withstand wear and abrasion, making them suitable for components subjected to constant friction.

Low-Speed Applications: These sheets excel in low-speed applications, providing durability and stability even under heavy loads.

OIL-FILLED CAST NYLON SHEET

Oil-filled cast nylon sheets are renowned for their exceptional wear properties and are specifically designed for applications requiring repetitive movement at high speeds under load.

Key Features of Oil-Filled Cast Nylon Sheets

Outstanding Wear Resistance: Oil-filled cast nylon sheets offer exceptional wear resistance, making them ideal for components subjected to continuous motion and high friction.

High-Speed Performance: These sheets are engineered for high-speed applications, providing reliable and durable solutions for a variety of industries.

OIL-FILLED CAST NYLON ROD

Oil-filled cast nylon rods are engineered to provide exceptional performance in applications demanding repetitive movement in high-speed conditions under heavy loads. This specialised grade of cast nylon is known for its superior wear properties and durability.

Key Features of Oil-Filled Cast Nylon Rods

Enhanced Wear Resistance: Oil-filled cast nylon exhibits excellent resistance to wear and friction, making it ideal for components subject to continuous motion.

High-Speed Durability: These rods are specifically designed for applications that operate at high speeds while carrying substantial loads, ensuring reliability and longevity.

Self-Lubricating: The infused oil provides continuous lubrication, reducing maintenance requirements and ensuring smoother operation.

In the realm of engineering plastics, the choice between oil-filled cast nylon and wax-filled cast nylon is not a one-size-fits-all decision. Each material offers its own set of advantages and considerations, making it vital to understand your project's unique requirements.

As your trusted engineering plastics supplier, ePol is here to guide you through this decision-making process. We offer a wide range of cast nylon solutions and expert support to ensure your project's success.

When it comes to selecting the perfect material for your industrial needs, reach out to us for personalised guidance. Our commitment to quality, performance, and your satisfaction sets us apart in the field of engineering plastics.

For more detailed information on our cast nylon offerings and expert insights, be sure to visit our cast nylon sheet and cast nylon rod pages.

Remember, in the world of engineering plastics, the right choice can mean the difference between success and setbacks in your projects. Make an informed decision today with the assistance of ePol.