At a glance

- Explore Acetal Copolymer (POM-C) with ePol, Australia's Leading Engineering Plastics Supplier.

- From Manufacturing Insights to Real-World Applications: Unravelling the Power of POM-C.

- Efficient, Transparent, and Quality-Driven: Your Guide to POM-C with ePol – Transforming the Landscape of Engineering Plastics in Australia.

In the realm of engineering plastics, Acetal Copolymer, commonly known as POM-C, stands out as a versatile and high-performance material.

This comprehensive blog aims to provide an in-depth exploration of POM-C, covering its chemical composition, manufacturing intricacies, properties, benefits, and diverse applications across various industries.

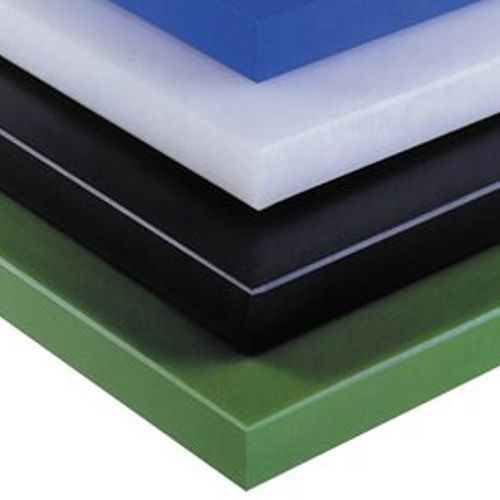

POM-C

Polyoxymethylene, or POM, is a renowned engineered plastic known for its exceptional properties. Acetal Copolymer, abbreviated as POM-C, is a specific type of POM.

In its white semi-crystalline state, POM-C exhibits remarkable tensile strength and creep resistance, making it a preferred alternative to metals in various applications.

Manufacturing Intricacies

The production process of POM-C involves the distillation of hydrocarbons into fractions, followed by polymerisation in the presence of catalysts. Depending on the desired type (homopolymer or copolymer), different manufacturing processes are employed.

For POM-C, the copolymer variant is commonly used, involving the conversion of formaldehyde to trioxane, followed by polymerisation with co-monomers like dioxolane and ethyl oxide.

Properties of POM-C

POM-C possesses a distinctive set of properties that make it a sought-after engineering plastic. With a melting point of 162-173 degrees Celsius, POM-C demonstrates excellent heat resistance.

Its high tensile strength of 63 MPa and flexural strength of 90 MPa contribute to its suitability for precision components. Additionally, POM-C offers a low coefficient of friction, high rigidity and is 100% recyclable.

Benefits of POM-C

Its strength, chemical resistance, and impact resistance make it ideal for applications in challenging environmental conditions.

POM-C's low friction coefficient and durability make it a preferred choice for movable parts in vehicles, construction units, and precision components.

Applications Across Industries

POM-C finds extensive applications across diverse industries.

In the automotive sector, it is utilised in vehicle fuel sender units, power windows, door locks, and more.

Precision components like gears, bushings, and fasteners benefit from POM-C's high mechanical strength.

The material's application extends to the medical sector, food industry, sports equipment, and even 3D printing with ongoing research in this field.

Key Considerations for Material Selection

Choosing between POM-C homopolymer and copolymer depends on specific requirements.

Homopolymers are stiffer with high tensile strength, suitable for applications demanding hardness.

Copolymers, on the other hand, offer better dimensional stability and resistance to chemicals and abrasion.

Environmental Considerations

While POM-C is known for its durability and recyclability, it's crucial to consider its toxicity when inhaled in vapour/liquid form.

In its solid crystalline form, POM-C is considered food-safe, with FDA-approved grades available for use in the food industry.

Acetal

Acetal, known by various names such as POM and Delrin, stands as a robust engineering thermoplastic, meticulously utilised in the precision manufacturing of components demanding high stiffness, dimensional stability, and low friction. Under esteemed brands like Dynex, our Acetal holds FDA and RoHS approval, ensuring quality and compliance.

Application of Acetal

- Bearings and bushings

- Pump and valve parts

- Gears

- Jigs and fixtures

- Food processing

- Packaging machinery parts

- Wear pads

- Electrical components

Performance Charateristics

- High strength

- Low friction

- Excellent wear properties in wet and dry environments

- Easy to machine

FAQs

Are Acetal and Delrin the same?

While Acetal and Delrin share similarities, they differ significantly. Acetal encompasses two resins: Copolymer acetal (POM-C) and homopolymer acetal (POM-H or Delrin®), each with distinct advantages.

Advantages of POM-C over Delrin®:

- Better dimensional stability

- Improved resistance to hot water and caustics

- Lower coefficient of friction, enhanced impact and wear properties

Advantages of Delrin® over POM-C:

- Greater stiffness with higher flexural modulus

- Slightly higher tensile and impact strength

- Harder, resulting in a lower coefficient of friction

How strong is acetal?

Acetal boasts outstanding flexural and tensile strength, reaching up to 9,500 psi, coupled with excellent hardness and dimensional stability.

Does acetal absorb water?

Acetal exhibits low moisture sensitivity in wet environments and showcases resistance to various chemicals, including many solvents.

Is acetal recyclable?

Yes, acetal is recyclable, allowing for reground and sustainable usage.

Is acetal food-grade plastic?

Absolutely, our acetal is FDA approved, meeting stringent standards for food-grade applications.

In conclusion, Acetal Copolymer (POM-C) emerges as a standout material in the realm of engineering plastics, offering a unique combination of mechanical strength, chemical resistance, and versatility.

This blog has provided a comprehensive overview, from its chemical composition to real-world applications, aiming to cater to materials enthusiasts, engineers, and industry professionals seeking a deeper understanding of POM-C's significance.