At a glance

- Unrivaled Performance: Cast Nylon bearings offer exceptional load-bearing ability, wear resistance, and self-lubricating properties, making them a superior choice for diverse applications across industries.

- Versatile Applications: From automotive and aerospace to medical equipment, Cast Nylon bearings excel in critical components, ensuring durability, noise reduction, and reliability.

- Sustainable Solution: Cast Nylon's energy-efficient manufacturing process, extended lifespan, and reduced maintenance contribute to waste reduction and align with sustainability goals.

Plastic bearings have irrevocably transformed the landscape of industrial engineering, offering a lightweight, corrosion-resistant, and versatile alternative to traditional metal bearings. Among these innovative plastic materials, Cast Nylon stands out as the unrivalled "king of plastic bearings." Its unique mechanical properties and manufacturing capabilities make it a preferred choice across many industries. In this comprehensive exploration, let's dive into the fascinating world of Cast Nylon bearings, dissecting their benefits, applications, and the process behind their creation.

Understanding Cast Nylon: The Versatile Plastic Bearing

Cast Nylon, a type of thermoplastic polymer, is revered for its adaptability and exceptional mechanical properties. It's manufactured through a casting process that imparts the material with a unique molecular structure, resulting in a material that can be tailored to specific applications. This versatility has made Cast Nylon bearings highly sought after in industries that demand high-performance solutions.

Benefits of Cast Nylon Bearings

Unparalleled Load Bearing Ability

At the heart of Cast Nylon's superiority is its ability to bear heavy loads with remarkable ease. This material's load-carrying capacity is unparalleled in the world of plastics, often rivalling that of traditional steel bearings. This extraordinary strength empowers Cast Nylon bearings to thrive under extreme mechanical stresses, ensuring reliability and longevity.

Superior Wear and Abrasion Resistance

Cast Nylon bearings' wear and abrasion resistance sets them apart from other materials. They withstand the grind of constant movement and friction without succumbing to deterioration. This exceptional durability translates to reduced maintenance requirements and extended service life.

Self-Lubricating Properties

Cast Nylon's low coefficient of friction grants it inherent self-lubricating properties. This feature diminishes the need for frequent lubrication, streamlining maintenance routines and reducing operational costs. Industries that require consistent performance in remote or difficult-to-access locations benefit significantly from this attribute.

Dampening and Shock Absorption

The molecular architecture of Cast Nylon not only provides mechanical strength but also contributes to natural dampening and shock absorption capabilities. In applications where vibrations and impacts are concerns, such as heavy machinery or automotive components, these properties mitigate noise and stress, ensuring smooth operations.

Replacing Steel with Cast Nylon Bearings

The transition from traditional steel bearings to Cast Nylon bearings represents a paradigm shift in engineering solutions. While steel has long been the default choice for its strength, Cast Nylon's benefits often outweigh steel's advantages. Cast Nylon's lightweight nature, corrosion resistance, and self-lubricating properties make it an attractive replacement, resulting in enhanced efficiency and reduced maintenance costs.

Applications of Cast Nylon Bearings

Automotive Industry

In the automotive sector, Cast Nylon bearings contribute to the seamless functioning of various components. They find their place in suspension systems, steering columns, and hinges, where their durability, corrosion resistance, and noise reduction capabilities are highly valued.

Industrial Machinery

Industrial machinery relies on Cast Nylon bearings to endure the demands of heavy loads and harsh working environments. They are essential in conveyor systems, rollers, gears, and other mechanisms driving production and efficiency.

Aerospace Sector

Aerospace engineering demands materials that are lightweight, durable, and reliable. Cast Nylon bearings meet these criteria, finding application in aircraft components that require precise performance and operational longevity.

Medical Equipment

The medical field benefits from the precision and reliability of Cast Nylon bearings in critical equipment. They play a pivotal role in diagnostic devices, patient beds, and other medical machinery, ensuring consistent and safe operation.

Manufacturing Process of Cast Nylon Bearings

The production of Cast Nylon bearings involves a meticulous casting process. During polymerization, the material's molecular structure is carefully controlled, resulting in a tailored product with desired properties. This process allows engineers to create bearings that excel in load-bearing capacity, wear resistance, and self-lubrication.

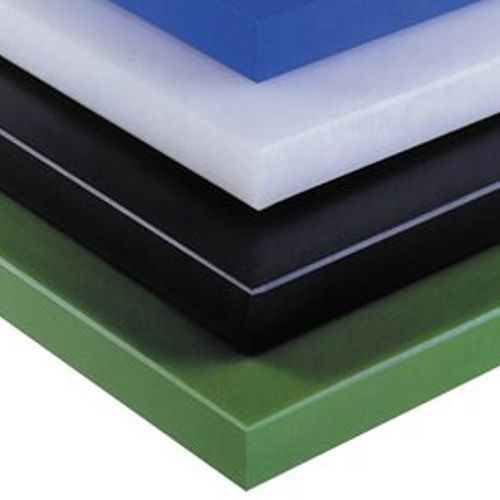

Comparing Cast Nylon with Other Plastic Bearings

In comparison to other plastic bearings like POM and PEEK, Cast Nylon offers a comprehensive blend of mechanical properties. While POM excels in low-friction applications and PEEK boasts high-temperature resistance, Cast Nylon often strikes a balance that suits a wider range of demanding scenarios.

Maintenance and Lifespan of Cast Nylon Bearings

Cast Nylon bearings demand minimal maintenance due to their self-lubricating properties. Regular inspections and simple cleaning routines can significantly extend their lifespan, ensuring consistent and reliable performance over the long term.

Considerations for Choosing Cast Nylon Bearings

Selecting the right bearing material involves careful consideration of load requirements, environmental conditions, and operational temperatures. Consulting experts in the field can aid in making informed decisions that optimise performance and longevity.

Environmental Impact and Sustainability

Cast Nylon's manufacturing process is more energy-efficient compared to traditional metal production methods. Furthermore, its durability and extended lifespan contribute to waste reduction and fewer replacements, aligning with sustainability objectives.

Challenges and Limitations of Cast Nylon Bearings

While Cast Nylon offers an array of benefits, it's essential to acknowledge its limitations. High temperatures can influence its performance, and exposure to certain chemicals may lead to degradation. Understanding these boundaries is crucial for successful application.

Future Innovations in Cast Nylon Bearing Technology

As material science continues to advance, Cast Nylon bearing technology is expected to evolve. Innovations might focus on expanding the material's temperature range, further enhancing its mechanical properties, and exploring novel applications.

Embracing the Excellence of Cast Nylon Bearings

In closing, Cast Nylon bearings have rightfully earned their title as the "king of plastic bearings." Their exceptional load characteristics, coupled with a multitude of other advantages, make them indispensable in diverse industries. As the pursuit of efficient, durable, and reliable solutions continues, Cast Nylon's role in shaping the future of engineering remains pivotal.

If you are looking to make the switch to cast nylon look no further than E Pol! With more dimensional stability and strength it can help you save time and money in the long run while maintaining the efficacy of your operations.