At a glance

- Types of Cast Nylon: Explore variations like nylon 6, nylon 66, and speciality

- Advantages of Cast Nylon: Cast nylon offers exceptional wear resistance, low friction, and machinability.

- Material Selection Guidelines: Consider factors like temperature, chemical compatibility, and load-bearing capacity while selecting cast nylon products for your specific use.

When considering engineering materials, cast nylon emerges as a remarkably versatile and reliable option. Its distinct characteristics have made it a preferred choice among engineers and designers, granting it extensive utility across diverse industries. In this in-depth guide, we invite you to delve into the world of cast nylon, where we will navigate through its numerous variations, empowering you to make well-informed choices tailored to your precise requirements and application demands. Our exploration of cast nylon will provide valuable insights, enabling you to harness the full potential of this exceptional engineering material for your projects.

The Basics of Cast Nylon

Before we dive into the diverse world of cast nylon variations, let's start with the fundamentals. Cast nylon, also known as polyamide, is a high-performance engineering plastic renowned for its exceptional properties. It is valued for its excellent wear resistance, self-lubricating properties, low friction, and remarkable strength. These qualities make cast nylon an ideal choice for a multitude of applications, from machinery components to industrial gears.

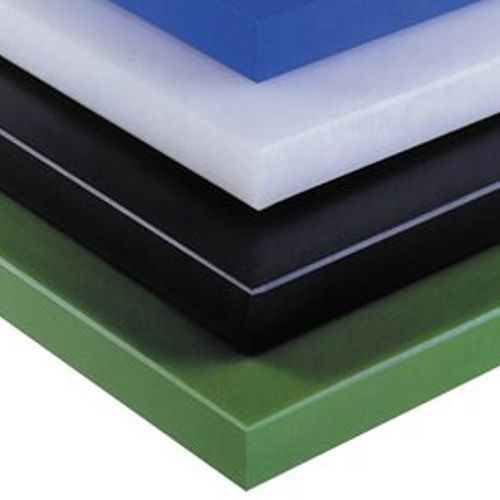

Cast nylon is renowned for its exceptional versatility and widespread use in various industries. Cast nylon is typically available in two primary forms: cast nylon rod and cast nylon sheet.

This unique material is manufactured through a casting process, resulting in its distinctive properties, including high strength, excellent wear resistance, and impressive chemical stability. Its importance in engineering applications cannot be overstated.

Cast nylon is favoured in industries ranging from automotive to food processing due to its ability to outperform traditional materials. It offers remarkable durability and dimensional stability, making it an ideal choice for components subjected to high mechanical stress and demanding environments. Its versatility, coupled with the ability to tailor formulations for specific needs, makes cast nylon an invaluable resource in modern engineering.

Advantages of Cast Nylon

The advantages of cast nylon are truly remarkable, making it a preferred choice in various industries. Cast nylon exhibits a distinctive set of properties that set it apart:

High Wear Resistance: Cast nylon boasts exceptional wear resistance, which makes it ideal for components subjected to constant friction and abrasion. This property ensures a prolonged lifespan and reduced maintenance costs.

Low Friction: With a low coefficient of friction, cast nylon reduces the energy required for movement, resulting in decreased wear and heat generation. This attribute is invaluable in applications where efficiency and smooth operation are critical.

Excellent Machinability: Cast nylon is easily machinable, allowing for intricate designs and precision manufacturing. Its ability to maintain tight tolerances simplifies the production process and ensures consistent product quality.

Durability in Challenging Environments: Cast nylon's durability and resistance to chemicals and moisture make it suitable for challenging environments. It excels in applications ranging from conveyor systems in food processing to bushings in heavy machinery.

Cast nylon's unique combination of properties, including wear resistance, low friction, and machinability, positions it as an indispensable material for industries requiring durability and performance in demanding conditions.

Types of Cast Nylon

Cast nylon comes in a diverse array of variations, each tailored to meet specific engineering needs. These variations include nylon 6, nylon 66, and speciality grades like oil-filled and wax-filled nylon.

Nylon 6: Known for its excellent mechanical properties and ease of processing, nylon 6 is a versatile choice for applications requiring strength and toughness. It's commonly used in gears, bearings, and wear-resistant components.

Nylon 66: Nylon 66 offers enhanced heat resistance and dimensional stability, making it suitable for high-temperature applications. It finds its place in industries like automotive, where components are exposed to elevated temperatures.

Oil-Filled Nylon: Oil-filled nylon combines the inherent properties of cast nylon with added lubrication. This type reduces friction and wear, making it ideal for applications like bushings and gears, where smooth operation is crucial.

Wax-Filled Nylon: Wax-filled cast nylon sheets offer enhanced wear resistance, catering to applications with frequent low-speed, high-load movements. It delivers superior performance in scenarios demanding durability and prolonged repetitive motion. Wax-filled nylon products are ideal for various engineering applications, such as sliding components and slide rails.

The diversity in cast nylon types allows engineers to select the most appropriate material based on specific application requirements, whether it's strength, heat resistance, lubrication, or stiffness.

Applications of Cast Nylon Across Industries

Cast nylon's versatility (be it cast nylon road or cast nylon sheet) extends across a wide spectrum of industries, proving its worth in various applications.

Industrial Sector: Across cranes and heavy industrial applications, cast nylon emerges as a quintessential material, seamlessly blending durability with versatility. Renowned for its exceptional load-bearing capacity, cast nylon components elevate operational efficiency, ensuring longevity in challenging environments. The unique self-lubricating properties of cast nylon contribute to reduced friction, enhancing the reliability of crucial crane mechanisms.

Aerospace: Cast nylon's lightweight and durability make it suitable for aerospace applications. It's used in components like aircraft engine parts, control systems, and aircraft interiors, where its high strength-to-weight ratio is advantageous.

Manufacturing: The manufacturing industry relies on cast nylon for conveyor system components, including wear strips, chain guides, and rollers. Its low friction properties reduce maintenance and enhance productivity.

Healthcare: Cast nylon's biocompatibility and resistance to sterilisation methods make it valuable in healthcare. It's used in medical equipment and devices like surgical instruments, dental tools, and prosthetic components.

In these industries, cast nylon excels in components requiring high durability, low friction, and resistance to wear and chemicals. Its adaptability to diverse applications underscores its value as a go-to material for engineers and manufacturers seeking reliable and long-lasting solutions.

Considerations for Material Selection for Various Industries

Selecting the appropriate type of cast nylon product, such as cast nylon sheet or cast nylon rod, for a specific application is critical to ensure optimal performance. Several key factors should be considered:

Temperature Resistance: Evaluate the operating temperature range of the application. For high-temperature environments, nylon 66 might be preferable, while standard nylon 6 suits moderate temperatures. Speciality grades, like glass-filled nylon, offer enhanced temperature resistance.

Chemical Compatibility: Assess the exposure to chemicals or solvents. Cast nylon exhibits excellent resistance to many chemicals, but oil-filled nylon may be more suitable for applications involving lubricants or hydraulic fluids.

Load-Bearing Capacity: Determine the load-bearing requirements of the component. Nylon 6 and 66 offer good strength, but for high-load applications, glass-filled nylon or higher-density variants may be necessary.

Friction and Wear: Consider the level of friction and wear the component will experience. For low friction and wear, oil-filled nylon is a viable option.

Environmental Conditions: Analyse the environmental conditions, such as humidity or UV exposure, as these can affect material properties. Speciality formulations with UV stabilisers can be chosen for outdoor applications.

By carefully assessing these factors, you can make informed decisions, ensuring that the chosen cast nylon type aligns with the specific demands of the application, thus maximising the material's effectiveness and longevity.

How to Choose the Right Cast Nylon Variation

Selecting the most suitable cast nylon variation for your specific needs can be a crucial decision. To make an informed choice, consider the following factors:

Application Requirements: Understanding the demands of your application is paramount. Are you looking for a material that offers high load-bearing capacity? Do you need excellent wear resistance or low friction? Each cast nylon variation has its unique set of properties that cater to specific needs.

Environmental Factors: Consider the environment in which your cast nylon components will operate. If they are exposed to UV radiation or harsh weather conditions, black-cast nylon or UV-stabilised variations may be necessary.

Lubrication Needs: For applications that require self-lubrication, oil-filled cast nylon is a top choice. It reduces friction and extends component life, making it suitable for many industrial and automotive applications.

Aesthetics and Branding: If your project involves design elements or branding considerations, the colour of cast nylon can play a significant role. Custom colours are available to match your design requirements.

Where to Find Quality Cast Nylon

Now that you have a comprehensive understanding of the various cast nylon variations, it's essential to source your materials from a reputable supplier; ePol, a leading provider of engineering plastics in Australia, offers a wide range of high-quality cast nylon products, including sheets and rods in various sizes and types.

Visit the ePol website to explore our extensive catalogue and discover the perfect cast nylon solution for your project, including cast nylon sheets and cast nylon rods.

Cast nylon is a remarkable engineering material with a universe of variations to cater to diverse needs and applications. Whether you require sheets or rods, natural or coloured cast nylon, or specialised types like oil-filled or wax-filled variations, understanding your application requirements is key to making the right choice. With the information provided in this comprehensive guide, you are now equipped to select the ideal cast nylon variation for your specific project, ensuring optimal performance and durability. Choose wisely, and let cast nylon's exceptional properties work to your advantage.