At a glance

- PTFE is a versatile material used in various industries for its non-stick surface, heat resistance, and chemical inertness.

- PTFE is very resistant to water and has a contact angle of around 110 degrees.

- ePol is a top PTFE supplier in Australia. They offer high-quality PTFE products for industrial applications, such as sheets, rods, and films.

Polytetrafluoroethylene (PTFE) is a remarkable material renowned for its unique properties and wide range of applications. One of its most notable characteristics is its hydrophobic nature, making it invaluable in various industrial and engineering contexts.

This article will explain PTFE's water-repelling properties, its uses, and why it is important in engineering plastics in Australia.

What is PTFE?

PTFE, commonly known by the brand name Teflon©, is a synthetic fluoropolymer of tetrafluoroethylene. It is known for its non-stick properties, high thermal resistance, and excellent chemical inertness. These attributes make it a popular choice in industries ranging from cookware to aerospace engineering.

The Science Behind Hydrophobicity

Hydrophobicity refers to a material's ability to repel water. This property is quantified by measuring the contact angle of a water droplet on the material's surface. A contact angle greater than 90 degrees indicates hydrophobicity, while an angle less than 90 degrees indicates hydrophilicity. PTFE exhibits a contact angle of approximately 110 degrees, making it highly hydrophobic.

The hydrophobic nature of PTFE arises from its molecular structure. The carbon-fluorine bonds in PTFE are among the strongest in organic chemistry, providing the material with its non-reactive surface. Additionally, the arrangement of these bonds creates a surface that minimises the interaction with water molecules, enhancing its water-repellent properties.

Advantages of PTFE's Hydrophobic Properties

-

Non-Stick Surface

PTFE's ability to repel water contributes to its non-stick nature, making it ideal for use in cookware and industrial applications where adhesion is undesirable. This property also facilitates easy cleaning and maintenance.

-

Chemical Resistance

The hydrophobic and non-reactive surface of PTFE makes it resistant to a wide range of chemicals. Resistance is very important in harsh chemical environments because it helps prevent damage and makes components last longer.

-

Low Friction

PTFE's low surface energy results in minimal friction, which is beneficial in applications such as bearings, gears, and sliding mechanisms. This low friction reduces wear and tear, enhancing the durability and efficiency of mechanical systems.

Applications of Hydrophobic PTFE

-

Coatings and Linings

PTFE is extensively used in coatings for its non-stick and chemical-resistant properties. It is used to coat the inside of pipes, tanks, and other equipment in the chemical industry to prevent damage and pollution.

-

Medical Devices

PTFE is used to coat catheters and other medical devices in the medical field. Its hydrophobic surface reduces the risk of bacterial adhesion and biofilm formation, ensuring the safety and sterility of medical equipment.

-

Electronics

PTFE is used in the electronics industry to insulate cables and components. Its hydrophobicity and chemical resistance protect sensitive electronic parts from moisture and chemical damage.

-

Automotive Industry

PTFE's hydrophobic properties are leveraged in the automotive industry for various applications. Nitrile rubber is commonly used in fuel hoses, brake linings, and seals. Its ability to resist water and chemicals improves the performance and durability of automotive parts.

-

Food Processing

The food industry benefits from PTFE's non-stick and hydrophobic characteristics. Conveyor belts, baking sheets, and other equipment are used to release food products and maintain hygienic surfaces easily.

Enhancing Hydrophobicity of PTFE

PTFE's natural hydrophobicity can be further enhanced through various methods. One common way is to use PTFE powder, which can be added to other materials to make them more water-repellent. This technique is particularly useful in creating hydrophobic coatings for fabrics, glass, and other surfaces.

Using PTFE Powder

PTFE powder can be mixed with other substances to create composite materials with enhanced hydrophobic properties. Composites are used for waterproof coatings, antifouling coatings, and protective layers in various applications.

Surface Treatments

Surface treatments such as plasma etching and chemical vapour deposition can modify the surface of PTFE, increasing its hydrophobicity. These treatments create micro- and nanoscale roughness on the PTFE surface, amplifying its water-repellent characteristics.

PTFE in Engineering Plastics

In Australia, PTFE is a critical component of the plastic engineering sector. Its unique properties make it an ideal choice for manufacturers looking to produce high-performance, durable, and reliable plastic components. As a PTFE supplier, Epol offers a range of PTFE products, including sheets, rods, and films, catering to diverse industrial needs.

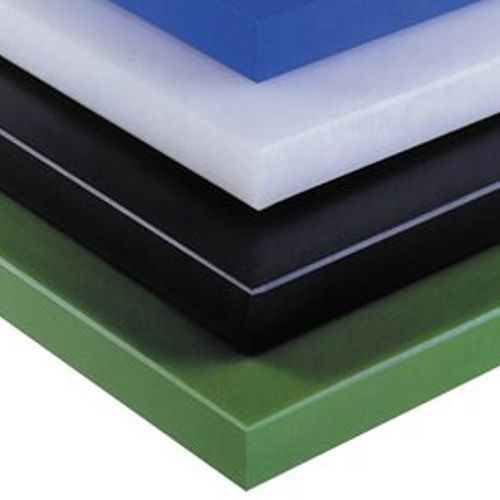

PTFE Sheets

PTFE sheets are widely used in applications requiring chemical resistance, low friction, and high-temperature stability. They are ideal for gaskets, seals, and liners in the chemical processing and food production industries. The sheets can be easily machined to precise dimensions, making them suitable for custom applications in various sectors.

PTFE Rods and Films

PTFE rods and films are used in electrical insulation, bearing pads, and various mechanical components. Their exceptional properties ensure optimal performance in demanding environments. PTFE rods can be turned and milled into complex shapes, providing engineers with the flexibility to design innovative solutions for challenging applications. PTFE films, with their thin profile and excellent dielectric properties, are used in insulation and protective layers for sensitive electronic components.

Environmental Impact and Sustainability

While PTFE is a versatile and valuable material, its environmental impact must be considered. PTFE is a non-biodegradable material, and its production involves the use of perfluorooctanoic acid (PFOA), a substance that has raised environmental and health concerns. However, advances in manufacturing processes have led to the development of PFOA-free PTFE, reducing its environmental footprint.

Recycling PTFE

Recycling PTFE is challenging due to its high melting point and chemical inertness. However, initiatives are underway to develop effective recycling methods. Recycled PTFE can be used in applications where the highest purity is not required, such as in composite materials and as fillers in other plastics.

Future of PTFE in Engineering Plastics

The demand for PTFE in engineering plastics is expected to grow, driven by its unique properties and expanding applications. Innovations in PTFE processing and the development of new composites will further enhance its performance and sustainability.

Emerging Applications

Emerging applications of PTFE include 3D printing, where its high-temperature stability and chemical resistance make it suitable for creating complex and durable components. Additionally, the development of PTFE-based nanocomposites is opening new possibilities in fields such as energy storage, biomedical devices, and advanced coatings.

Why Choose PTFE from Epol?

As a leading PTFE supplier in Australia, Epol provides high-quality PTFE products that meet stringent industry standards. Our products are designed to deliver superior performance, reliability, and longevity in a wide range of applications. PTFE sheets, rods, or custom-fabricated components, we have the expertise and resources to meet your needs.

ePol is committed to providing engineering plastics solutions that meet our customers' evolving needs. Our extensive inventory and technical support ensure that you have access to the right materials and expertise for your projects.

Understanding PTFE's hydrophobic properties is crucial for leveraging its full potential in various applications. Its unique molecular structure and resulting characteristics make it an invaluable material in numerous industries. For high-quality PTFE products in Australia, Epol stands as a trusted supplier committed to delivering excellence in engineering plastics. Explore our range of PTFE products and discover how they can enhance your industrial applications.

For more information on our products and services, visit ePol's website.