At a glance

- PTFE (Polytetrafluoroethylene) and Teflon™ are fundamentally the same material, with Teflon™ being Chemours' trademarked name.

- PTFE/Teflon™ features high chemical resistance low surface energy, and more ideal for various industrial applications.

- PTFE/Teflon™ is widely used in the chemical, electronics, and medical industries.

Materials like PTFE and Teflon are known for their exceptional properties and wide range of applications. These two names are often used interchangeably. But are they really the same? Let's delve into the specifics to understand the similarities and differences between PTFE and Teflon. Furthermore, why these materials are so vital in various industries?

What is PTFE and Teflon?

PTFE (Polytetrafluoroethylene) is a high-molecular-weight polymer consisting solely of carbon and fluorine atoms. This unique structure grants PTFE its exceptional properties, making it a standout material in the realm of engineering plastics. On the other hand, Teflon™ is simply the trade name for PTFE, trademarked by Chemours, a spin-off from DuPont.

While PTFE and Teflon™ are fundamentally the same material, the name Teflon™ often evokes the image of non-stick cookware in the minds of many. However, PTFE's applications extend far beyond the kitchen, encompassing a broad spectrum of industrial uses.

Properties of PTFE

High chemical resistivity

One of the most distinguishing features of PTFE plastic is its high chemical resistivity. PTFE is virtually inert to most chemicals, making it ideal for containers and pipelines handling reactive and corrosive substances. This property alone places PTFE at the forefront of materials used in harsh chemical environments.

Low surface energy

In addition to its chemical resistance, PTFE boasts the lowest surface energy among solid materials. This characteristic ensures that substances do not easily adhere to their surface, which is why PTFE is commonly used in non-stick coatings for cookware. The low surface energy also translates to excellent anti-friction properties, making PTFE an ideal choice for applications requiring low resistance levels.

High thermal stability

Another critical attribute of PTFE is its high thermal stability. PTFE can withstand extreme temperatures without degrading, maintaining its integrity and performance in conditions that would compromise other polymers. This thermal stability is crucial for applications in high-heat environments, such as in aerospace and industrial processing.

Applications of PTFE

The unique properties of PTFE make it indispensable in various industries.

Chemical industry

In the chemical industry, PTFE is used for lining containers and pipes that handle aggressive chemicals, ensuring durability and safety. Its non-reactive nature also makes it suitable for use in laboratory equipment and components.

Electronics industry

PTFE's excellent dielectric properties are highly valued in the electronics sector. PTFE is used to insulate wiring and components in high-frequency applications, such as coaxial cables and hookup wires. These applications benefit from PTFE's ability to resist breakdown and maintain performance under electrical stress.

Medical industry

Medical applications also leverage PTFE's benefits. Its biocompatibility and inertness make it suitable for use in implants and surgical instruments. PTFE is often used in prosthetics, grafts, and other medical devices where compatibility with the human body is essential.

Teflon™: The Trademarked Name

While PTFE is the scientific term, Teflon™ is the trademarked name that has become synonymous with non-stick cookware and other consumer applications. DuPont coined the name Teflon™ and is now managed by Chemours. Despite being the same material, the branding of Teflon™ has led to its widespread recognition and association with quality and reliability.

Properties and Applications of Teflon™

Teflon™ shares all the properties of PTFE, but its branding has led to a few distinct associations. For instance, Teflon's low coefficient of friction is one of its most celebrated features. This property makes Teflon™ ideal for applications where smooth movement and low wear are crucial, such as in bearings, bushings, and sliding applications.

The good dielectric properties of Teflon™ also make it an excellent insulator in electrical applications. Its ability to maintain stability and performance in high-frequency environments is leveraged in the production of cables and connectors used in telecommunications and data transmission.

Teflon's versatility extends to the medical field as well. Due to its inertness and compatibility with the human body, it is used in the manufacture of various medical devices and implants. Teflon™ is also used to fabricate non-stick coatings for surgical instruments, ensuring ease of use and improved performance.

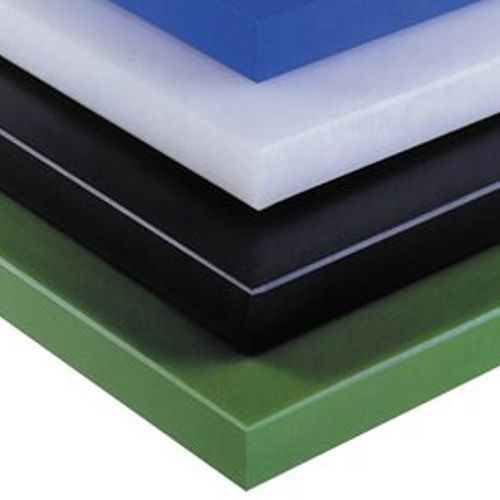

PTFE Sheets and Suppliers

For high-quality PTFE materials, sourcing from reputable suppliers is crucial. ePOL is a leading provider of engineering plastics in Australia, offering several key benefits:

- Extensive Product Range: ePOL supplies a wide selection of engineering plastics in sheet and rod forms, including PTFE plastic.

- Competitive Pricing: With live online pricing and inventory, you can easily order materials at the best prices, helping you plan your manufacturing pipeline efficiently.

- Convenient Shipping: Free nationwide shipping on orders over $150 (excluding GST), with tracking and dedicated logistics support ensuring reliable deliveries.

- Efficient Back Order System: Stay updated on stock arrivals with ePOL’s comprehensive back order system.

- Flexible Payment Options: For a smooth purchasing experience, check out with a credit card or take advantage of excellent trading terms.

- Expert Customer Support: ePOL’s experienced staff provide expert advice and timely support to ensure you get exactly what you need.

Register online today to experience why ePOL is a top choice for engineering plastics in Australia, streamlining your operations and ensuring high performance and efficiency in your applications.

In conclusion, PTFE and Teflon™ are essentially the same material, with Teflon™ being the branded name for PTFE. Both terms refer to a polymer with extraordinary properties, including high chemical resistance, low surface energy, and high thermal stability. These characteristics make PTFE an invaluable material in various industries, from chemical processing to electronics and medical applications.

Understanding the nuances between PTFE and Teflon™ helps in making informed decisions when selecting materials for specific applications. Whether referred to as PTFE or Teflon™, the benefits of this remarkable polymer are clear, and its role in modern engineering plastics is undeniable.

For those in need of high-quality PTFE materials, sourcing from a reliable PTFE supplier ensures that you receive the best products for your needs. Whether in the form of PTFE sheets or other configurations, the right materials can significantly enhance the performance and longevity of your applications. As the demand for engineering plastics in Australia continues to grow, PTFE remains a cornerstone material, driving innovation and efficiency across industries.