At a glance

- PTFE offers superior chemical resistance and thermal stability.

- HDPE is strong and durable for applications like piping and bottles.

- Acetal is ideal for precision parts with excellent dimensional stability.

Engineering plastics have transformed industries around the world by providing greater performance in a wide range of applications. Polytetrafluoroethylene (PTFE) stands out due to its unusual features.

However, how does it compare to other engineering plastics?

In this detailed comparison, we examine PTFE's unique properties, benefits, and potential drawbacks. Furthermore, we compare it to other common engineering polymers.

What are PTFE plastics?

PTFE, also known as Teflon©), is a high-performance fluoropolymer made of carbon and fluorine atoms. Its molecular structure expressed as [CF2-CF2]n, is similar to that of polyethylene, but the hydrogen atoms have been swapped with fluorine. This substitution provides PTFE with superior chemical resistance, thermal stability, and electrical inertness.

Here are the key properties of PTFE

PTFE plastic is renowned for several key properties:

- Chemical Resistance: PTFE is extremely resistant to most chemicals, including acids, bases, and solvents.

- Thermal Stability: It can endure continuous service temperatures of up to 260°C and remains thermally stable without substantial degradation below 440°C.

- Electrical Insulation: PTFE has outstanding electrical insulating characteristics, even in hot and moist environments.

- Low Friction: It has one of the lowest friction coefficients among technical polymers.

- Non-stick Surface: Because of its non-stick properties, PTFE is suited for use in cookware and other industrial applications.

Despite these benefits, PTFE has drawbacks. The material is prone to deformation with time and wear. In addition, it exhibits significant changes in size around its glass transition temperature and poses challenges in conventional methods of manufacture, including melting.

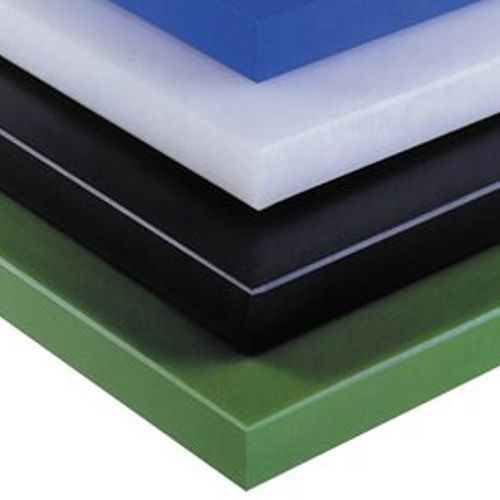

Comparing PTFE with Other Engineering Plastics

PTFEs are comparable to other popular materials such as polyethylene (PE), polyethylene terephthalate (PET), polycarbonate (PC), and polyamide (PA, commonly known as nylon).

1. Polyethylene (PE)

Polyethylene is one of the most widely used plastics, known for its versatility and cost-effectiveness. However, when compared to PTFE:

- Chemical Resistance: While PE has good chemical resistance, PTFE outperforms it, particularly in harsh chemical environments.

- Temperature Resistance: PTFE can handle much higher temperatures than PE.

- Mechanical Properties: PE is generally more flexible but lacks the superior mechanical strength and creep resistance of PTFE.

2. Polyethylene Terephthalate (PET)

PET is widely used in packaging, textiles, and automotive components. It is valued for its strength and chemical resistance.

- Thermal Stability: PET has a lower thermal resistance compared to PTFE, making PTFE a better choice for high-temperature applications.

- Wear Resistance: PTFE exhibits better wear and frictional properties, making it more suitable for non-lubricated applications.

- Electrical Properties: PTFE’s electrical insulating properties are superior to PET’s, which is critical in electrical and electronic applications.

3. Polycarbonate (PC)

Polycarbonate is known for its high impact resistance and optical clarity. It is commonly used in eyewear lenses, CDs, and bulletproof glass.

- Impact Resistance: While PC has excellent impact resistance, PTFE could be stronger in this regard.

- Thermal and Chemical Resistance: PTFE surpasses PC in both thermal and chemical resistance.

- Friction: PTFE’s low coefficient of friction and non-stick properties are far superior to those of PC.

4. Polyamide (Nylon)

Nylon is prized for its mechanical strength, elasticity, and abrasion resistance. It is used in applications ranging from automotive components to textiles.

- Moisture Absorption: Nylon tends to absorb moisture, which can affect its mechanical properties. PTFE, on the other hand, has negligible water absorption.

- Chemical Resistance: PTFE offers better chemical resistance than Nylon.

- Thermal Properties: PTFE can withstand higher temperatures than nylon.

5. High-Density Polyethylene (HDPE)

High-density polyethylene (HDPE) is a versatile and widely used plastic known for its strength, durability, and chemical resistance. It is used in a range of industries, from packaging to piping systems.

- Mechanical Properties: HDPE is known for its excellent tensile strength and impact resistance. However, PTFE offers superior mechanical properties under high temperatures and has better resistance to wear and tear.

- Chemical Resistance: While HDPE is highly resistant to many chemicals, including acids and bases, PTFE surpasses it in resisting even more aggressive chemicals, making it ideal for more demanding environments.

- Thermal Properties: HDPE has a lower melting point compared to PTFE. HDPE can be used in temperatures up to around 120°C, whereas PTFE can withstand continuous use at temperatures up to 260°C.

6. Acetal (Polyoxymethylene or POM)

Acetal, also known as polyoxymethylene (POM), is a high-strength, low-friction engineering plastic known for its excellent dimensional stability and wear resistance. It is commonly used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

- Mechanical Properties: Acetal has excellent rigidity and is highly resistant to creep and fatigue, which makes it a strong contender for precision mechanical parts. However, PTFE has a lower coefficient of friction and a broader temperature range. Often, this makes it the better choice for applications involving extreme temperatures and chemical exposure.

- Chemical Resistance: Acetal is resistant to many solvents and chemicals but can be attacked by strong acids and bases. PTFE offers better chemical resistance, enduring even the most aggressive chemicals.

- Thermal Properties: Acetal can operate continuously up to 100°C, whereas PTFE can withstand much higher temperatures, making it more versatile for high-temperature applications.

7. Polyether Ether Ketone (PEEK)

It is a high-performance engineering plastic known for its excellent mechanical properties, thermal stability, and chemical resistance. It is one of the most advanced engineering plastics available today.

- Mechanical Properties: PEEK offers exceptional mechanical strength and is highly resistant to wear and fatigue, comparable to PTFE. However, PTFE’s unique low-friction properties often give it an edge in applications requiring minimal wear and tear.

- Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, similar to PTFE. However, PTFE still offers superior resistance in some of the most extreme chemical environments.

- Thermal Properties: PEEK can operate continuously at temperatures up to 250°C, which is close to PTFE’s maximum operating temperature of 260°C. Both materials exhibit excellent thermal stability. However, PTFE’s slightly higher temperature resistance can be advantageous for specific applications.

Applications of PTFE and Other Engineering Plastics

The exceptional qualities of PTFE render it essential in a wide range of applications. PTFE sheets are utilised in the food sector to provide non-stick surfaces in cookware. Its exceptional chemical resistance makes it highly suitable for use in gaskets, seals, and linings within the chemical processing industry.

The low friction and non-stick properties of PTFE are employed in several applications, including bearings and bushings.

Other engineering plastics also have their niches:

PE: Widely used in packaging, containers, and piping due to its versatility and cost-effectiveness.

PET: Commonly found in beverage bottles, food packaging, and synthetic fibres.

PC: Used in applications requiring high impact resistance and transparency, such as safety goggles and optical disks.

Nylon: Due to its strength and flexibility, nylon is employed in automotive parts, industrial components, and textiles.

High-density polyethylene (HDPE) is used in applications like corrosion-resistant piping, plastic bottles, and geomembranes for landfill sites. Its strength and durability make it a popular choice for these applications.

Acetal (POM): It is favoured for precision parts such as gears, bearings, and bushings, where its dimensional stability and mechanical strength are crucial.

Polyether Ether Ketone (PEEK): It is used in high-performance applications in aerospace, automotive, and medical devices, where exceptional mechanical strength and thermal stability are required.

Role of Fillers in Enhancing PTFE

PTFE has the notable benefit of being able to be combined with fillers to improve its characteristics. Fillers such as glass fibre, carbon, graphite, and bronze can greatly enhance the mechanical strength, wear resistance, and thermal conductivity of PTFE.

For example, PTFE filled with glass is more resilient to deformation over time and works effectively in applications involving elevated temperatures.

Carbon-infused polytetrafluoroethylene (PTFE) exhibits enhanced hardness and thermal conductivity, rendering it well-suited for several applications, including the use of piston rings in compressors.

Graphite-filled polytetrafluoroethylene (PTFE) exhibits a very low coefficient of friction, making it highly suitable for applications that do not require lubrication.

Here are the PTFE Products in ePol

When looking for PTFE products, especially in Australia, it’s important to find a reliable PTFE supplier who offers a variety of forms and grades to meet diverse needs. Below are some commonly available PTFE products:

- PTFE-0.25-FILM: PTFE roll, 50 meters x 1.2 meters x 0.25 mm thick.

- PTFES-01: PTFE virgin sheet, 01 mm thick x 1.2 meters x 1.2 meters.

- PTFES-03: PTFE virgin sheet, 03 mm thick x 1.2 meters x 1.2 meters.

- PTFES-06: PTFE virgin sheet, 06 mm thick x 1.2 meters x 1.2 meters.

- PTFES-10: PTFE virgin sheet, 10 mm thick x 1.2 meters x 1.2 meters.

- PTFES-12: PTFE virgin sheet, 12 mm thick x 1.2 meters x 1.2 meters.

- PTFES-15: PTFE virgin sheet, 15 mm thick x 1.2 meters x 1.2 meters.

- PTFES-20: PTFE virgin sheet, 20 mm thick x 1.2 meters x 1.2 meters.

- PTFES-25: PTFE virgin sheet, 25 mm thick x 1.2 meters x 1.2 meters.

- PTFE-VS-30: PTFE virgin sheet, 30 mm thick x 1 meter x 1 meter.

- PTFES-30: PTFE virgin sheet, 30 mm thick x 1.2 meters x 1.2 meters.

These products can be tailored to specific applications, ensuring that industries benefit from PTFE’s unique properties.

PETP and Polycarbonate Products available in ePol

In addition to PTFE, other engineering plastics such as PETP and polycarbonate also have significant industrial applications. Some notable products include:

PETP Rods

- PETR-20: PETP natural rod, 20 mm diameter x 1 meter.

- PETR-30: PETP natural rod, 30 mm diameter x 1 meter.

- PETR-40: PETP natural rod, 40 mm diameter x 1 meter.

- PETP-TF-20: PETP PTFE filled rod, 20 mm diameter x 1 meter.

- PETP-TF-30: PETP PTFE filled rod, 30 mm diameter x 1 meter.

- PETP-TF-40: PETP PTFE filled rod, 40 mm diameter x 1 meter.

Polycarbonate Sheets

- TUFFAKS-3-AR2: Polycarbonate abrasion + UV resistant, 3 mm thick, 2.4 x 1.2 meters.

- TUFFAKS-4.5-AR2: Polycarbonate abrasion + UV resistant, 4.5 mm thick, 2.4 x 1.2 meters.

- TUFFAKS-6-AR2: Polycarbonate abrasion + UV resistant, 6 mm thick, 2.4 x 1.2 meters.

- TUFFAKS-6-AR2-1.8: Polycarbonate abrasion + UV resistant, 6 mm thick, 2.4 x 1.8 meters.

- TUFFAKS-9.5-AR2: Polycarbonate abrasion + UV resistant, 9.5 mm thick, 2.4 x 1.2 meters.

- TUFFAKS-9.5-AR2-1.8: Polycarbonate abrasion + UV resistant, 9.5 mm thick, 2.4 x 1.8 meters.

- TUFFAKS-12.7-AR2: Polycarbonate abrasion + UV resistant, 12.7 mm thick, 2.4 x 1.2 meters.

- TUFFAKS-12.7-AR2-1.8: Polycarbonate abrasion + UV resistant, 12.7 mm thick, 2.4 x 1.8 meters.

PTFE and Other Engineering Plastics in Australia

When selecting a supplier, consider factors such as material quality, supplier reputation, and technical support. Reliable suppliers offer a range of PTFE grades, including food, medical, and high-purity grades, to meet diverse industry needs.

PTFE exhibits superior chemical resistance, thermal stability, and reduced friction qualities when compared to other technical plastics. These attributes render it a superb option for high-performance applications.

Nevertheless, the selection of material ultimately relies on the particular demands of the application. Although PTFE demonstrates exceptional performance in various aspects, other industrial polymers such as PE, PET, PC, and Nylon possess their distinct benefits.

Australia-based individuals looking for top-notch PTFE sheets and other technical plastics can greatly benefit from collaborating with a reliable PTFE provider.

Ultimately, PTFE and other engineering plastics offer a variety of solutions to fulfil your requirements.