At a glance

- From its exceptional wear resistance to its suitability for medical implants and aerospace components.

- Find the perfect fit for your application, whether it's high-friction liners or low-friction machinery parts.

- Explore market growth projections, innovations like x-ray detectable variants, and future applications in electric vehicles.

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is an engineering plastic known for its unmatched abrasion resistance, toughness, and impact strength. As an essential product offered by engineering plastics suppliers, UHMWPE stands out with its hydrocarbon-based linear homopolymer structure, exhibiting high thermoplasticity and a semicrystalline nature with superior crystallinity.

Its unique properties, including minimal coefficient of friction and excellent wear resistance, make it a preferred choice for UHMWPE suppliers and a key material in various sectors. UHMWPE's exceptional qualities have led to its use in critical applications - from prosthetic joints to energy-absorbing road safety systems.

UHMWPE sheets play a crucial role in manufacturing protective materials for defence and thermal management. This underscores the importance of selecting the suitable UHMWPE grade for specific needs.

What is UHMWPE?

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is recognised for its exceptional combination of properties, making it a highly sought-after material across various industries. Its characteristics include:

Versatility and Durability

Known for its high abrasion and wear resistance, UHMWPE also boasts low friction and good chemical resistance, making it adaptable for a wide range of applications.

Thermoplastic Properties

As a polyethylene thermoplastic, it maintains high shape retention alongside its thermoplastic characteristics, offering advantages in manufacturing and end-use applications.

Environmental Resistance

Exhibiting low moisture absorption, UHMWPE retains its key physical properties across a broad temperature spectrum, from -30° C to 82° C, enhancing its utility in diverse environmental conditions.

UHMWPE's mechanical properties include moderate strength and stiffness, exceptional impact strength, and superior abrasion resistance. It is highly machinable, available in various grades, and has higher molecular weights that correlate to improved properties, such as density, abrasive resistance, and impact strength.

The material's molecular structure is characterised by highly long chains, with a molecular mass between 3 and 9.2 million amu. Its resistance to a wide range of chemicals, combined with self-lubricating properties and a low coefficient of friction, further underscores its versatility.

Grades of UHMWPE Explained

UHMWPE is available in a variety of forms and grades, each tailored for specific applications and performance requirements. Understanding these differences is crucial for selecting the suitable material for your needs:

Forms of UHMWPE

UHMW Liners: Ideal for applications requiring low friction and high wear resistance.

UHMW Parts: Custom parts that leverage UHMWPE's durability and resistance.

UHMW Wood Replacement: Offers the durability of plastic with the appearance of wood.

X-ray Detectable UHMW: Designed for use in food processing equipment where detectability is crucial.

Reprocessed UHMW: An economical, recycled option for less critical applications.

Grades Based on Friction Factor:

High Friction Applications:

Friction factor 0.10 to 0.22, suitable for environments where grip is essential.

Moderate Friction Applications:

Friction factor 0.05 to 0.10, balancing slip and grip.

Low Friction Applications:

Friction factor 0.05 to 0.08 for the smoothest operation.

Speciality Grades:

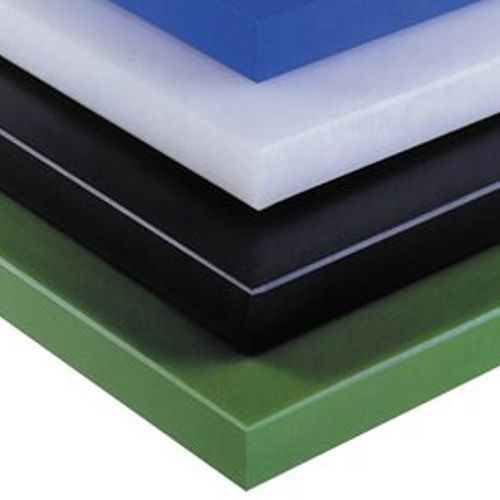

● OKULEN ® 500 natural FN0000

● OKULEN ® 500 yellow FN1000

● OKULEN ® 500 red FN3000

● OKULEN ® 500 blue FN5100

● OKULEN ® 500 AB blue FN5990

● OKULEN ® 500 green FN6000

● OKULEN ® 500 black FN9000

● OKULEN ® 500 UV black FN9100

● OKULEN ® 500 AST black FN9200

● OKULEN ® 500 REG. Green FN6000

● OKULEN ® 500 REG. Black FN9000

● OKULEN ® 500 REG. UV black FN9100

● OKULEN ® 500 REG. Black and white FN9005

● OKULEN ® 500 REG. Colourful FN9009

Enhanced Bearing and Wear & FDA-Compliant Grades

These grades are specifically designed for high performance and compliance with food safety regulations.

Customisation options, including sizes, widths, thicknesses, and colors, are available to tailor UHMWPE to meet various application requirements.

Applications of Different UHMWPE Grades

UHMWPE's versatility and superior properties have led to its widespread application across various industries, each benefiting from a specific grade of UHMWPE to meet unique requirements:

Industrial and Engineering Applications

Chute, Hopper, and Truck Bed Liners: These liners leverage UHMWPE's high abrasion resistance for durability and efficiency in material handling.

Wear Strips and Guide Rails, Star Wheels, and Idler Sprockets: Utilising their low friction and wear resistance for smooth operation in machinery.

High-Speed Conveyors and Packaging Machinery Parts: Benefitting from UHMWPE's toughness and impact strength for reliable performance.

Defence and Aerospace

Vehicle Armour and Ballistic Protection: Taking advantage of UHMWPE's high impact strength and resistance to cuts for enhanced safety.

Aircraft Components and Structural Reinforcements: Employing its resistance to chemicals, moisture, and corrosion for long-lasting applications.

Medical Field

Orthopaedic Implants and Joint Replacements: Capitalising on UHMWPE's biocompatibility and wear resistance for improved patient outcomes.

Prostheses and Body Armour: Utilising UHMWPE fibres for their strength, lightness, and wear resistance, offering increased mobility and protection.

This diverse range of applications underscores UHMWPE's adaptability and efficiency in meeting the specific needs of different sectors, from industrial engineering to medical advancements.

Selecting the Right UHMWPE Grade for Your Needs

Selecting the correct UHMWPE grade for specific applications hinges on understanding the material's molecular weight and its correlation with performance characteristics. Here's a breakdown to guide the selection process:

General Equipment Machinery Parts

Molecular Weight: 3-5 million

Key Properties: High wear resistance and self-lubricating

Applications: It is ideal for components that undergo regular wear and tear but require minimal maintenance. Examples include gears, bearings, and sliding elements.

High Wear Liners

Molecular Weight: No less than 5 million

Key Properties: Excellent wear resistance

Applications: It is suited for environments with abrasive materials. Typical uses include liners for chutes, coal bins, truck bodies, hoppers, and granary inside walls, where durability is paramount.

Customisation Options

UHMWPE Sheets: These are available in a variety of sizes, colours, and special features, catering to a wide range of industry needs.

Special Features: These include antistatic, self-lubricating, flame-retardant, food-grade, shielding neutron-grade, and anti-UV. These options allow for tailored solutions that meet the unique requirements of each application, ensuring optimal performance and compliance with industry standards.

Challenges and Considerations in Processing UHMWPE

Processing UHMWPE presents unique challenges due to its high molecular weight, which leads to high viscosity and a lack of fluidity. This characteristic complicates its processing using standard polymer methods.

Exceptional grades of UHMWPE in granular form have been developed for injection moulding, yet they necessitate high injection pressures, significantly higher than most polymers.

Processing Techniques and Considerations

Injection Moulding: Requires high injection pressures (e.g., 110 MPa) 13.

Thermal Degradation Prevention: Ensuring optimal product quality necessitates avoiding thermal degradation.

Use of Solvents: Techniques involving solvents like mineral oil and xylene demand extensive post-processing for solvent reclamation.

Supercritical Fluids (SCFs): Utilising N2 or CO2 as plasticisers to reduce viscosity and enhance processability.

Research efforts focus on optimising the injection moulding process to enhance the mechanical and tribological properties of UHMWPE.

Moreover, innovative approaches like Microcellular Injection Moulding (MIM) introduce supercritical fluids into the polymer during the injection process, forming tiny gas bubbles that dissolve in the polymer matrix.

This technique, which involves a sudden pressure drop in the mould cavity, facilitates the creation of a foamed product without the need for a packing cycle, offering a novel solution to processing challenges.