Engineering plastics play a crucial role in various industries, including automotive, aerospace, medical, and manufacturing. We offer superior performance, durability, and design flexibility compared to traditional materials. For this reason, choosing the right engineering plastic for your application is critical to ensure the best performance and longevity.

Engineering Plastics Online Pty Ltd (ePOL) is a partnership between three international companies and a leading supplier of high-quality plastic manufacturers in Australia. We offer a wide range of materials that are suitable for various applications, from simple to complex projects. In this article, we will take a closer look at ePOL's stock availability and range of engineering plastics.

ePOL's Stock Availability and Range of Engineering Plastics

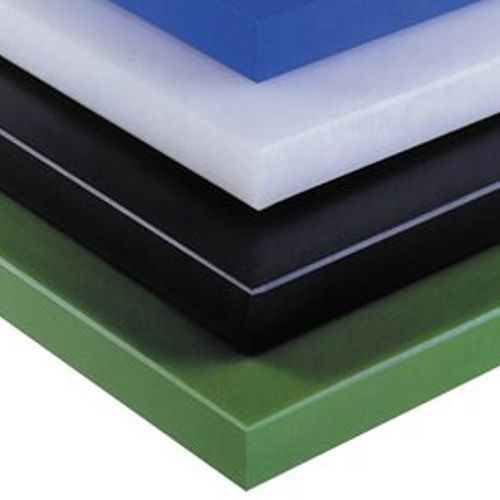

ePOL prides itself on having a vast stock availability of over 700,000 products, making it easy to find the right engineering plastic for your project. Our comprehensive range of engineering plastics includes popular materials such as Acetal, Cast Nylon, HDPE, PEEK, PET, Polycarbonate, PTFE, and UHMWPE. With ePOL, you can be confident that you will find the engineering plastic you require when you need it.

Acteal plastic

Acetal is a highly sought-after engineering thermoplastic known for its hard and rigid characteristics. It is commonly used to manufacture parts that require high stiffness, dimensional stability, and low friction. Also known as POM and Delrin, it is available in various forms and brands, including Dynex. Acetal is approved by the FDA and RoHS, making it suitable for food processing and electrical components. Acetal has excellent wear properties, is easy to maintain, and is highly resistant to moisture, chemicals, and solvents. It is used in the manufacturing of bearings, bushings, gears, and pump and valve parts, among others. Acetal comes in two types of resins, homopolymer acetal (POM-H) or Delrin®, and copolymer acetal (POM-C). Both have advantages. They share the advantages of low friction, high strength, and excellent wear properties in both wet and dry environments. Acetal is an excellent choice for applications that require high performance, and dimensional stability.

Cast nylon plastic

Cast nylon is a popular plastic choice for many mechanical machine parts due to its toughness, wear resistance, tensile strength, and lubricity. It is also known by several brand names, including Nylacast®, Sustamid®, and Tecast®. Available in rod and sheet, cast nylon is used for rollers, wheels, bearings, gears, and many other components. It boasts a high degree of crystallinity, very good wear and abrasion resistance, and good damping properties. Cast nylon also has very low levels of internal stress, making it easy to process. However, it is not recommended for use in wet applications as moisture can cause it to enlarge. When choosing between extruded nylon and cast nylon, factors to consider include stress levels, dimensional stability, strength, and operating temperature.

HDPE Plastics

HDPE or high-density polyethylene is a rigid, semi-crystalline plastic with high tensile strength and excellent resistance to hot and cold extremes. It is widely used in various industries such as mining, oil/gas, agriculture, and marine due to its durability and resistance to corrosion and chemicals. HDPE is easy to weld, fabricate, and machine, making it suitable for applications like chemical tanks, cutting boards, playground systems, outdoor cabinetry and furniture. HDPE is FDA-approved, and it's low moisture absorption and excellent surface make it ideal for food preparation. Although it has limitations such as poor temperature capability and stress cracking, HDPE is highly recyclable and does not produce harmful emissions during production or use.

PEEK plastics

PEEK, or Polyether Ether Ketone, is a semi-crystalline material known for its exceptional mechanical properties, temperature and chemical resistance. It is a preferred choice for many high-performance applications in industries such as aerospace, medical, and food processing. PEEK can be used to manufacture a range of components, including bushings, bearings, seals, pump and valve components, and electrical connectors. This material is FDA-approved and is available in rod and sheet forms. Its excellent properties include high strength, stiffness, chemical and hydrolysis resistance, and easy machinability. Moreover, PEEK is fully recyclable, and it emits very low smoke and toxic gas emissions when exposed to flames.

PET

PET, or Polyethylene Terephthalate, is a versatile engineering plastic that is widely used in the packaging industry due to its unique combination of strength, durability, and clarity. PET is lightweight and has excellent chemical resistance, making it ideal for use in food processing machinery components, valve components, manifolds, and filler pistons. PET is also commonly used in wear pads, bearings and bushings, wheels and rollers, and packaging and machinery parts. It is a strong and stiff plastic with low moisture absorption and low thermal expansion, making it suitable for use in wet environments. Additionally, PET is stain-resistant and is generally considered a safe plastic, as it does not contain BPA. However, it is highly hygroscopic and moisture-sensitive, which can make it challenging to dry. PET is also highly flexible, making it an ideal choice for a range of applications.

Polycarbonate

It is a tough, transparent plastic material with high impact resistance, ideal for applications that require high strength and durability. PET is a highly recyclable plastic that is commonly used in food and beverage packaging, while Polycarbonate is a transparent plastic that is often used in the manufacture of safety glasses, electrical components, and automotive parts.

PTFE Plastics

PTFE, also known as Teflon©, is a high-performance engineering plastic that is renowned for its excellent slip characteristics and superior thermal, electrical, and chemical properties. This material is highly stable at temperatures up to 260 degrees celsius, making it suitable for use in high-temperature environments.

PTFE is available in rod and sheet forms commonly used in many industrial applications such as seals and gaskets, valve and fitting components, pump parts, manifolds, semiconductor equipment, scientific equipment, chemical-resistant tubing, bearings, and bushings. PTFE offers outstanding chemical resistance, extremely low friction, softness and formability, good weathering resistance, and performs well at elevated temperatures. PTFE is FDA-approved, and ingestion of PTFE is not known to be toxic.

UHMWPE Plastics

UHMWPE, or ultra-high molecular weight low-pressure polyethylene, is a highly versatile engineering plastic that is known for its excellent resistance to abrasion, chemicals and water absorption, as well as its high impact strength and low friction properties. Although it is not suitable for high-temperature applications, it is a popular choice for use in a variety of industries, including food processing, material handling and packaging, and marine and wastewater treatment. UHMWPE comes in rods and sheets and is easy to fabricate. It is extremely tough and durable, making it ideal for use in wear strips, bearings, gears, chute liners, and conveyor systems. Our UHMWPE is FDA-compliant and is manufactured by the brand Okulen. It is non-toxic, non-hazardous and has a zero water absorption level. Furthermore, it is also recyclable, making it an environmentally friendly option for various applications.

ePOL's Competitive Pricing and Quality Guarantee

ePOL's website offers a user-friendly interface that makes it easy to search for and purchase engineering plastics online. We have a vast stock availability of over 700,000 products, including PEEK plastic, polycarbonate sheet, PTFE sheet, acetal plastic, cast nylon sheet, and HDPE plastics. Our extensive range of materials allows us to cater to a wide range of industries and applications.

One of our key selling points is the commitment to competitive pricing without compromising on the quality of the products. This is evident on our website, where we offer the most competitive prices in the market. Our pricing strategy is designed to help businesses save money without sacrificing quality.

ePOL's quality guarantee is another crucial aspect. We partner with three international companies (over 100 years of combined experience in the industry) to ensure that we source high-quality materials at competitive prices. Our partnership also allows us to stay up-to-date, featuring the latest trends and innovations in the industry, ensuring the most cutting-edge solutions for our customers.

ePOL's Custom Solutions and Expert Customer Service

At ePOL, our commitment to providing custom solutions for unique requirements in uncompromised. We understand that different industries have specific needs and specifications, and we are committed to providing tailored solutions to meet those needs. Our team of experienced sales representatives is available to provide expert advice and support to help customers make informed decisions.

In addition to our custom solutions, ePOL is committed to providing excellent customer service. We have a fast turnaround time and offer a range of delivery options to ensure that our customers receive our orders on time and in perfect condition. Our website also features a range of resources and information to help customers learn more about our products and applications.

Choosing the right engineering plastics for your business can be challenging. However, with ePOL's commitment to quality, competitive pricing, and excellent customer service, you can rest assured that you are making the right choice.

ePOL's vast stock availability, wide range of engineering plastics, and custom solutions make us an ideal choice for businesses in Australia.

By choosing ePOL as your one-stop shop for high-quality engineering plastics, you are not only getting access to the latest innovations and materials but also to a team of experts dedicated to finding the right solutions for your unique requirements.

In summary, whether you need PEEK plastic, polycarbonate sheet, PTFE sheet, acetal plastic, cast nylon sheet, HDPE plastics, or any other type of engineering plastic, ePOL is your one-stop-shop. Choose ePOL today and experience the difference for yourself!