At a glance

- DYNEX and ePOL have partnered to increase cast nylon production, leading to faster delivery times.

- The increased production capacity allows DYNEX and ePOL to meet the growing demand for cast nylon products and customer demands.

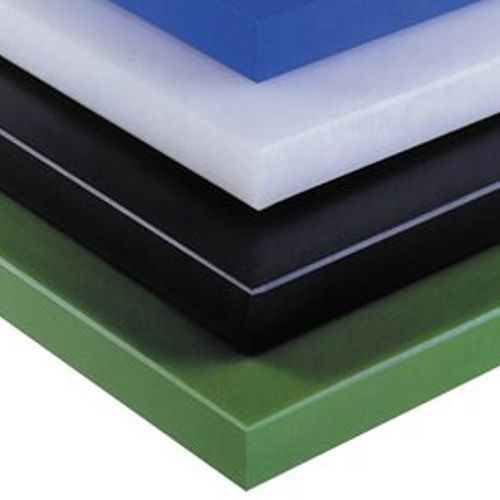

Cast nylon is a high-performance thermoplastic material that offers numerous benefits over traditional materials such as rubber and metal. It is an essential material in engineering applications because of its excellent physical and chemical properties, such as high strength, wear resistance, self-lubrication, and chemical resistance. Cast nylon sheets and cast nylon rods are commonly used in gears, bearings, skate rollers, levers, and other mechanical parts that require high durability and strength. Its excellent physical and chemical properties have made cast nylon an indispensable material in the aerospace, automotive, and construction industries.

ePOL, a leading supplier of engineering plastics in Australia, has partnered with DYNEX, a leading engineering plastics manufacturer in the Asia Pacific region, to improve cast nylon plastics' production and supply chain. Established in 1965, DYNEX has a long-rich history of manufacturing high-quality engineering plastics under an ISO9001-certified management system. Motivated to produce the highest quality engineering plastics in the market, the partnership of DYNEX and ePOL looks to double the cast nylon production and improve delivery times for customers.

Cast nylon sheets and cast nylon rods are popular products in engineering plastics in Australia. With DYNEX and ePOL's partnership, customers can enjoy faster delivery times for their cast nylon needs.

DYNEX's Expansion and Increased Production Capacity

DYNEX is a global leader in cast nylon production. Its partnership with ePOL is a strategic move to expand production capacity and improve delivery times of cast nylon in the market. DYNEX has invested in state-of-art equipment and technology to improve its manufacturing process. They can now produce large quantities of engineering plastics, such as cast nylon sheets, with faster turnaround times. DYNEX has been one of the frontrunners in technological achievements in engineering plastics in the Asia Pacific region. With their highly qualified experts, the company continues to innovate its production process.

DYNEX'S engineering plastic products ensure top-level quality in dimension control, size ranges, and physical properties. Motivated to provide customers with the best quality products, DYNEX stands firm in its principles even when moving with increased production capacity. The partnership with ePOL further solidifies its stand in quality service. DYNEX's increased production capacity is good news for customers who rely highly on cast nylon products for engineering applications. With better delivery times and quality control at the helm of this partnership, customers can easily access high-quality cast nylon sheets and rods, which is crucial for businesses operating on tight deadlines.

The Benefits of Cast Nylon

Cast nylon is a highly versatile thermoplastic material with endless applications. Because of its excellent physical and chemical properties, this engineering plastic offers several benefits over materials like metal and rubber. Some of the crucial benefits of cast nylon include the following:

- High strength and stiffness: Cast nylon is a rigid plastic that withstands high-stress levels. It has a compressive strength of 15,000 psi. Most plastics bend over time but cast nylon sheets possess excellent resistance to deformation.

- Wear resistance: It is highly resistant to wear, making it perfect for equipment parts constantly subjected to movement or friction (in equipment that requires constant sliding and rotation).

- Self-lubrication: Cast nylon formulations have excellent self-lubricating properties, so equipment operators do not have to manually lubricate valves or seals made from cast nylon. This cuts the maintenance requirements compared to rubber and metal parts.

- Chemical resistance: The chemical resistance of cast nylon sheets and rods makes it suitable for use in harsh environments with high chemical exposure.

- Lighter Weight: Equipment weight is a major concern in sectors with heavy use of engineering materials. Heavy weight means larger shipping time, shipping cost, and operating costs. Cast nylon is about 1/7th the weight of classic metals, giving it an edge over metal parts. The weight of cast nylon formulations will only significantly impact the overall weight of equipment.

- Heat Resistance: Cast nylon has good heat resistance, making it a perfect fit for equipment that generates significant heat while operating. The melting point of cast nylon is 430 °F.

ePOL's Partnership with DYNEX

ePOL's partnership with DYNEX is an important milestone for both companies committed to customer satisfaction and excellence in engineering plastics. This collaboration enables both companies to expand their product range and ensure an impeccable delivery time. With DYNEX's expertise in engineering plastic production, ePOL can now bring customers a wider range of cast nylon products, including cast nylon sheets.

ePOL's commitment to the highest quality material to the customers and supporting it with service and price second to none is well aligned with DYNEX's principles and values. The partnership brings together the expertise of two leading companies in engineering plastics, ensuring that customers now have access to the most advanced materials.

Fast Production and Delivery

Thank's to DYNEX's commitment to increased production, ePOL can now execute fast production and delivery times for all cast nylon products. This highly works in favour of businesses that rely on cast nylon products for their engineering applications. Fast production and delivery times mean companies can meet their deadlines and complete projects in hand on time. This improved work dynamic will help businesses ensure better operations and financial grounds.

With ePOL's online shopping convenience and digital reach and DYNEX's high-quality cast nylon products, a powerful synergy in engineering plastics is formed. This gives customers an easy and highly effective domain to browse, study, and purchase the products they need, knowing that they are of the highest quality in the market and are backed by excellent service. For customers, who are more confident in the traditional method of buying in person, ePOL has a highly professional sales team to attend to your needs.

The partnership between DYNEX and ePOL is a game-changer in the engineering plastics industry in Australia. With expanded production capacity and commitment to customer satisfaction from both parties, this synergy ensures faster customer production and delivery times. We understand the endless benefits of cast nylon products, and many engineering sectors rely on cast nylon products for various engineering applications.

Our confidence in our products increases when two leading companies in the industry come together. At ePOL, we are proud to partner with DYNEX, a company driven by customer preferences like ours. With this partnership at the forefront of engineering plastics in Australia, customers can trust ePOL to provide them with the highest quality material and better delivery times.