At a glance

- PEEK plastic is a high-performing thermoplastic with excellent mechanical, chemical and thermal properties.

- ePOL's partnership with DYNEX ensures the best quality PEEK plastic sheet for automotive, aerospace, and other engineering applications.

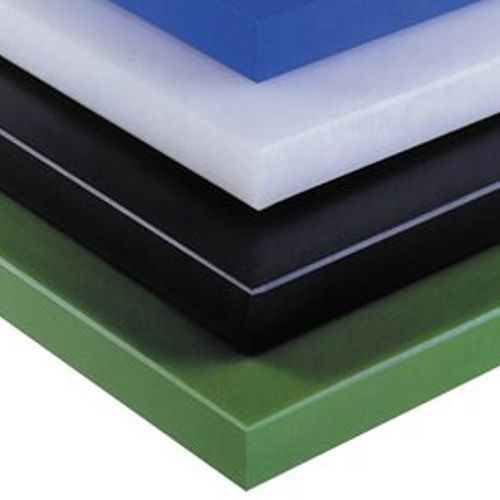

PEEK plastic (polyether ether ketone) is a high-performance polymer with endless applications due to its exceptional mechanical, chemical, and thermal properties. PEEK formulations like plastic sheet and peek fabricators are commonly used across various industries, such as automotive, aerospace, electronics, and medical. This colourless thermoplastic material is easy to mould into complex shapes, which makes it ideal for applications requiring intricate designs.

PEEK plastic is known for its high strength-to-weight ratio, low coefficient of friction, and excellent temperature resistance. Also, it is highly resistant to wear, chemicals, and abrasion, making it perfect for equipment used in harsh environments. Due to its unique characteristics, PEEK plastic has become a reliable material for manufacturers and plastic fabricators producing high-performance components or parts.

ePOL, as a leader in the engineering plastics industry, is proud to have partnered with DYNEX, a leading manufacturer of PEEK plastic sheets and other high-performance polymers. This partnership allows us to serve our customers with the best products. DYNEX has a proven record of manufacturing high-quality PEEK products and is highly committed to innovation and quality.

EPOL and DYNEX are committed to delivering top-notch PEEK plastic products to our valuable customers at affordable prices. Our partnership with the leading producer of engineering plastics in the Asia Pacific Region gives us access to the best PEEK plastic sheet and other products in the market. We can meet the most demanding requirement of our customers.

DYNEX's Production Capacity and Innovation for PEEK

DYNEX has pioneered innovation and production of PEEK plastic for over five decades. With modern production facilities and a team of highly experienced engineers and technicians, DYNEX can produce engineering plastics in various sizes and thicknesses, as well as custom-made PEEK parts. DYNEX has also supplied a range of semi-finished PEEK plastics in the shape of sheets and rods to match customer preferences. Their product range encompasses both general engineering plastics and high-performance materials.

DYNEX, a manufacturer of engineering thermoplastic products, stands out from the other plastic fabricators in the market due to its commitment to innovation and quality. The company has heavily invested in innovation over the years and continues to develop its operations to improve its production process and develop new applications for PEEK plastic. This has resulted in high-quality PEEK products that meet the highest market standards for customers who depend heavily on PEEK plastic sheets and PEEK plastic rods for their engineering applications.

Availability of PEEK and partnership with DYNEX

One of the biggest advantages of our partnership with DYNEX is the availability of high-performing PEEK plastic sheets and other products. The availability of PEEK plastics is a major concern for many companies that rely on its unique properties for their engineering products and applications. ePOL's partnership with DYNEX ensures our customers access a wider range of high-quality PEEK products. DYNEX has a large inventory of PEEK plastic in stock, meaning ePOL can now provide customers with fast and reliable delivery times.

In addition to a wider range of PEEK plastic and fast delivery times, our partnership with DYNEX ensures access to the best quality materials in the market. DYNEX has a rigorous quality control process to ensure the production of consistent and high-quality PEEK plastic sheets, rods, and other products. While considering engineering plastics used in semiconductor machinery, aerospace parts, medical instrument parts, and food processing machinery components, quality is very important. And quality is the facade of our partnership with DYNEX.

Moreover, this partnership offers our customers a chance to purchase PEEK products at an affordable price, which benefits companies with a limited budget but a huge demand for PEEK plastic. The cost-effectiveness that this partnership ensures is essential for companies looking to reduce their manufacturing costs without compromising on the quality or performance of their equipment.

The Benefits of PEEK for Engineering Applications

PEEK plastic offers several benefits in engineering applications, making it an ideal choice for aerospace, automotive, medical, and others. It has excellent mechanical strength and heat and chemical resistance. In addition, it allows excellent environmental resistance and dimensional integrity. Below are some major benefits of PEEK plastic.

Longer Lifespan: PEEK plastic has high corrosion resistance compared to traditional materials, such as stainless steel, aluminium, and bronze, used in various engineering applications. The higher corrosion resistance of PEEK materials ensures a longer lifespan, even in places with high humidity.

Weight Reduction: PEEK materials have a superior strength-to-weight ratio, which helps reduce the overall weight of equipment. Engineers can use PEEK formulations to replace heavier metal parts.

Resistance to High Temperatures: Materials made from PEEK plastic can maintain their dimensional stability even under high temperatures. PEEK plastic holds its physical properties up to 343 °C (662 °F), its melting point. So exposure to a higher temperature or high-pressure environment will not affect its rigidity.

Chemical Resistance: PEEK plastic has excellent resistance to chemicals. Also, it is resistant to seawater and hydrolysis, so it is not affected by the aqueous condition. This unique chemical property ensures high performance where other plastic polymers fall short.

Improved performance: PEEK plastic has a low coefficient of friction, allowing it to reduce friction and wear. Due to less friction, less energy is needed to operate equipment, which leads to improved efficiency. Also, less wear means fewer maintenance costs. Moreover, PEEK plastic has a low coefficient of resistance, allowing it to retain its shape and avoid deformation. A low coefficient of resistance contributes to improved engineering applications' efficiency, durability, and reliability.

In conclusion, ePOL's partnership with DYNEX is a step towards the future of engineering plastics in Australia. Committed to high-quality PEEK products for our customers at affordable prices, DYNEX's production capacity and innovation enable ePOL to meet our customers' demands.

PEEK plastic's unique and superior properties make this material a top choice for engineering applications that require high strength and chemical and thermal resistance. We encourage our customers to choose ePOL for their PEEK plastic needs and take advantage of our expert customer service. Choosing ePOL means you can have confidence in the PEEK plastic products you are getting. Our commitment to quality and DYNEX's expertise and innovative nature in PEEK plastic production make us the top choice for PEEK plastic sheets and other high-performing polymers in the market. Let's take your engineering applications to the next level together.