At a glance

- PTFE: Features, Advantages, Emerging Applications

- Superior properties: temperature, chemical resistance, insulation

- Industrial benefits: durability, versatility, safety

- Emerging uses: aerospace, medical, renewable energy

Polytetrafluoroethylene (PTFE), also renowned as Teflon®, is a marvel of engineering plastics that has revolutionised industries. First discovered in 1938, PTFE stands out for its exceptional resistance to high temperatures and chemicals. As a premier PTFE supplier in Australia, we at ePOL specialise in delivering high-quality PTFE products that cater to a broad range of industrial needs.

Superior properties of PTFE

PTFE is not your ordinary plastic. It is distinguished by its robust molecular structure, where fluorine atoms entirely flank carbon chains. This composition grants PTFE remarkable characteristics:

Unrivalled Temperature Resistance

PTFE is distinguished by its ability to operate effectively across a vast temperature range. From the frigid cold of -200°C to the extreme heat of +260°C, PTFE maintains its integrity and performance. This makes it an ideal choice for applications subject to drastic temperature variations, ensuring reliability where other materials might fail.

Superior Chemical Resistance

One of PTFE's most celebrated features is its resistance to almost all chemicals. This includes aggressive acids, bases, and solvents, making PTFE essential for industries like chemical processing, where exposure to harsh substances is common. Its ability to withstand such environments without degrading allows for its use in seals, gaskets, and linings where other materials would not suffice.

Optimal Electrical Insulation

PTFE possesses high dielectric strength, meaning it can resist electrical currents and prevent unwanted flow of electricity, making it an excellent insulator. This property is crucial in the electronics industry, where PTFE is used to coat wires and cables, protecting them from the environment and ensuring safe and efficient transmission of electrical signals.

Low Friction and Non-Stick Surface

The low coefficient of friction of PTFE is not just a technical advantage but a practical one. It allows materials to slide over each other with minimal resistance. This non-stick quality is why PTFE is so valuable in cookware and industrial applications where materials must be released easily from surfaces without sticking, such as in food processing equipment and mould release applications.

High Impact Resistance

Despite its non-stick surface, PTFE does not compromise on strength. It exhibits excellent impact resistance, which is particularly valuable in applications involving mechanical stress or where it must endure sudden, forceful interactions.

Weather and UV Resistance

PTFE's resilience extends to its ability to withstand long-term exposure to harsh weather conditions and ultraviolet light. This characteristic makes it an excellent material for outdoor applications, from aerospace components exposed to the rigours of outer space to architectural structures that must endure the elements.

Inertness and Biocompatibility

Being chemically inert, PTFE does not react with other substances, making it safe for use in medical and food applications. Its biocompatibility ensures that it can be used in the human body for implants and other medical devices without risk of rejection or harmful interactions.

Advantages of PTFE for Industrial Applications

PTFE's unique properties translate into significant industrial advantages

Polytetrafluoroethylene (PTFE) offers a multitude of advantages that make it a material of choice across a wide range of industrial applications. Its unique properties contribute to its widespread use and are particularly beneficial in settings where performance and reliability are crucial. Here, we explore how these advantages translate into real-world industrial benefits:

Durability and Longevity

PTFE's robustness against harsh chemicals and extreme temperatures contributes to its long lifespan. This durability means equipment and parts made with PTFE require less frequent replacement, reducing overall maintenance costs. Industries benefit from extended operation times and decreased downtime, enhancing productivity and efficiency.

Versatility

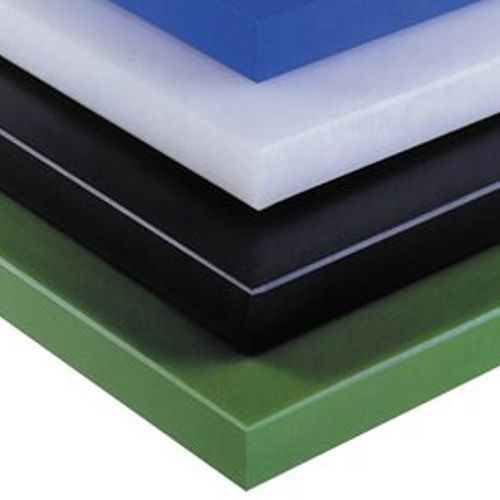

PTFE's ability to be moulded into various forms, such as sheets, rods, tubes, and films, makes it adaptable to numerous applications. Whether it needs to be machined into intricate parts or formed into large sheets for linings, PTFE’s versatility allows for its use across many sectors, including aerospace, chemical processing, and healthcare. This adaptability extends to its compatibility with a range of fillers that enhance certain properties for specific applications, such as glass fibres for increased wear resistance or carbon for improved thermal conductivity.

Operational Efficiency

The low friction coefficient of PTFE purchase enhances the performance of moving parts by reducing wear and tear and increasing energy efficiency. Machinery parts that operate with less resistance consume less energy, leading to cost savings and a lower environmental impact. This is especially important in industries such as automotive and manufacturing, where energy efficiency can directly influence operational costs and sustainability targets.

Safety and Compliance

PTFE is non-toxic and approved by regulatory bodies like the FDA for contact with food. This makes it an ideal choice for applications in the food and beverage industry, where safety and compliance with health regulations are paramount. PTFE's inertness ensures that it does not contaminate or react with the food products it comes into contact with, maintaining the purity and safety of consumable goods.

Enhanced Performance Under Extreme Conditions

PTFE's inherent qualities allow it to perform reliably in environments that would compromise many other materials. For example, in the aerospace industry, PTFE components can withstand the vacuum of space and extreme atmospheric temperatures, which are critical factors in the design and functionality of spacecraft and aeronautical engineering.

Reliability in Sealing Applications

PTFE's excellent sealing properties are due to its minimal deformation under load, making it an excellent choice for gasket and seal applications in heavy machinery and industrial pipelines. Its ability to maintain integrity and form under pressure ensures leak-proof sealing, which is crucial in preventing costly or dangerous leaks in chemical plants and oil refineries.

Corrosion Resistance

PTFE serves as an excellent protective barrier in environments where metallic components are prone to corrosion. Its resistance to weathering and UV light ensures that it does not degrade over time, which is essential for outdoor applications and equipment exposed to harsh environmental conditions.

Emerging Applications of PTFE in Industry

Innovation continues to drive the applications of PTFE, making it indispensable in both traditional and cutting-edge technologies:

Aerospace Applications: From aircraft coatings to components, PTFE ensures reliability under extreme conditions.

Medical Field: Its biocompatibility makes it suitable for a variety of medical devices, including catheters and surgical instruments.

Renewable Energy: PTFE components are crucial in enhancing the durability and performance of renewable energy systems.

The Role of PTFE in the Australian Market

As Australia continues to advance in technology and industry, the demand for reliable engineering plastics like PTFE has surged. ePOL, your trusted PTFE supplier, is committed to providing solutions that not only meet but exceed industry standards. Our PTFE sheets and other products are at the forefront of supporting essential sectors, including mining, pharmaceuticals, and food processing, ensuring that Australian industries remain competitive and innovative.

PTFE's unmatched properties and adaptability make it a fundamental material in numerous critical applications across Australia and beyond. At ePOL, we are dedicated to leveraging the full potential of PTFE to help our clients achieve unparalleled success in their operations. Explore our range of PTFE products and discover how we can assist in elevating your industrial capabilities.

Visit our website to learn more about our offerings and how PTFE can revolutionise your industry-specific applications.