At a glance

- Delve into the essence, properties, and applications of Ultra-High Molecular Weight Polyethylene.

- Explore how UHMWPE revolutionises industries from food processing to marine applications with its exceptional properties.

- Gain valuable insights into sourcing UHMWPE and understanding its potential for your next project.

In the world of materials science, certain innovations stand out for their remarkable properties and wide-ranging applications. One such material, which has become a cornerstone in various industries, is Ultra-High Molecular Weight Polyethylene (UHMWPE).

This blog post aims to demystify UHMWPE, exploring its essence, distinctive properties, and its diverse applications.

Whether you're a seasoned engineer, a procurement specialist seeking reliable engineering plastics suppliers, or simply a curious mind, this introduction to UHMWPE will shed light on why it's considered an indispensable material in modern engineering and design.

What is UHMWPE?

At its core, UHMWPE is a subset of polyethylene, the most common plastic used today. However, UHMWPE distinguishes itself by its ultra-high molecular weight, ranging between 3 and 9.2 million molecules. This is in contrast to the 10,000 to 20,000 molecules found in common linear polyethylene.

This gives UHMWPE a unique set of characteristics, including exceptional strength, durability, and resistance to wear and abrasion, while maintaining a lightweight.

It's no wonder that UHMWPE suppliers are sought after across various sectors for this high-performance material.

The Genesis of UHMWPE

The development of UHMWPE began in the 1950s and 1960s, driven by the quest for materials that could endure extreme conditions.

Its molecular structure is identical to ordinary polyethylene but with a much higher molecular weight, endows UHMWPE with performance capabilities far beyond those of standard plastics.

This high molecular weight is achieved through specialised synthesis processes, resulting in long polymer chains that entangle more effectively.

This entanglement confers strength and resilience, making UHMWPE a material of choice for demanding applications.

Distinguishing Features

One of the most striking characteristics of UHMWPE is its robustness combined with a surprisingly lightweight. This juxtaposition of strength and lightweight makes it a preferred material in applications where both durability and efficiency are required.

Its high abrasion resistance, for instance, surpasses that of carbon steel, making it 15 times more resistant to wear and tear. Additionally, its yarns are 40% stronger than those of aramid fibres, a testament to its superior strength.

Resistance Properties

UHMWPE's resistance to chemicals is another hallmark of its versatility. It can withstand the majority of alkalis and acids, organic solvents, degreasers, and electrolytic attacks.

This chemical inertness, coupled with its excellent dielectric properties, makes UHMWPE an ideal candidate for a wide range of industrial applications, from chemical processing equipment to electrical insulators.

Temperature Tolerance and Self-Lubrication

Despite its many strengths, UHMWPE does have its limitations, particularly in high-temperature applications.

It exhibits a lower melting point (around 297° to 305° F) compared to some polymers, which restricts its use in environments where high temperatures prevail.

However, its low coefficient of friction and self-lubricating nature partially offset this limitation, providing a smooth performance in many mechanical and dynamic applications without the need for additional lubricants.

Environmental and Health Safety

From an environmental and health perspective, UHMWPE shines brightly. It is non-toxic and has been endorsed by the FDA for use in food and medicine, signifying its safety in applications that directly impact human health.

Furthermore, its ability to float in water due to its low specific gravity opens up applications in marine and flotation devices.

Properties of UHMWPE

UHMWPE boasts an impressive array of properties that set it apart from other engineering plastics:

Wear-Resistance and Impact Resistance

UHMWPE's molecular structure endows it with unparalleled sliding friction resistance. Its wear resistance is significantly higher than that of metals and other plastics, making it ideal for applications where durability is crucial.

Hydrophobicity

With an extremely low water absorption rate, UHMWPE remains stable and unaffected in moist or wet environments, unlike many other materials that can swell or degrade over time.

High Tensile Strength

Thanks to its ultra-high molecular weight, UHMWPE possesses extraordinary tensile strength, allowing it to withstand severe stretching and pulling forces without breaking.

Low-Temperature Resistance

UHMWPE maintains its properties even at temperatures close to absolute zero, making it suitable for use in extremely cold environments.

Chemical Resistance

It exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents, ensuring durability in corrosive environments.

Lightweight

UHMWPE is less dense than other engineering plastics, offering significant weight savings for applications where every gram counts.

Non-Toxic

Being non-toxic and FDA-approved for use in food and medicine, UHMWPE is safe for applications involving direct contact with food products or human tissue.

Applications of UHMWPE

The unique properties of UHMWPE make it an ideal candidate for a myriad of applications. Let's touch on a few key areas:

Food Processing

In the food processing industry, UHMWPE plays a pivotal role, especially in components like bearings, gears, chute liners, and wear strips. Its non-toxic nature, coupled with resistance to wear and ease of cleaning, ensures safe and efficient operations.

Material Handling and Packaging

UHMWPE is invaluable for anti-static chute liners, wear strips, bearings, and gears within material handling and packaging machinery. Its durability and low friction reduce downtime and maintenance costs.

Conveyor Systems

For conveyor systems, UHMWPE's wear strips, gears, and chain guides minimise friction and wear, enhancing the lifespan and reliability of the systems. This is crucial in sectors where conveyor systems are the lifeline of operations.

Marine Applications

The marine industry benefits from UHMWPE's resistance to saltwater corrosion and abrasion. It's used in covers, doors, fixtures, and handles, providing durability in the harsh marine environment.

Waste Water Treatment Facilities

In wastewater treatment, the material's chemical resistance and durability make it suitable for wear strips, paddles, bearings, scraper blades, and chute liners. UHMWPE withstands the corrosive and abrasive conditions typical in such settings.

UHMWPE stands as a marvel of material science, offering an unmatched combination of durability, resistance, and versatility. Its applications span from the depths of the oceans to the confines of space, touching nearly every aspect of modern industry and technology.

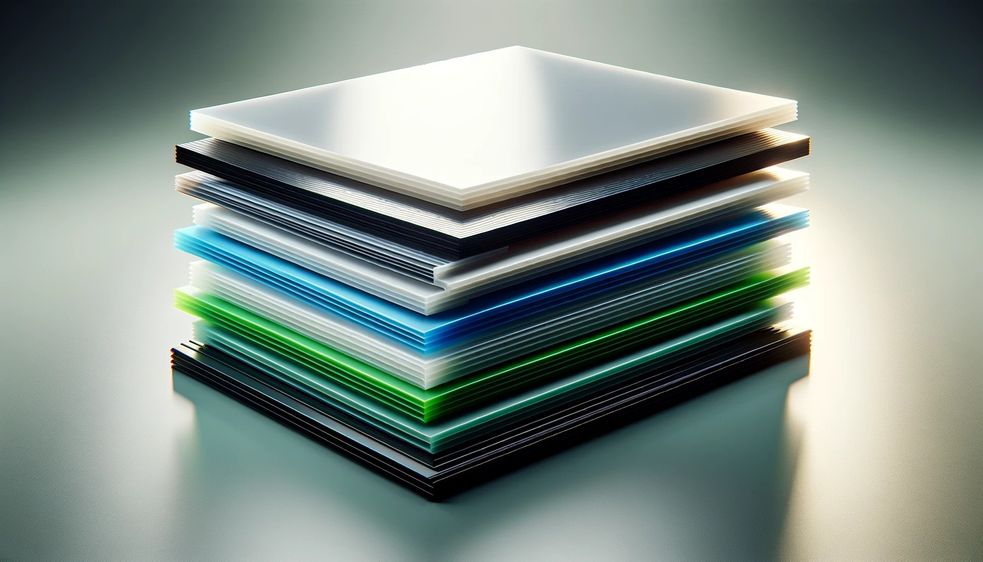

For those in search of an engineering plastics supplier or UHMWPE suppliers, understanding the fundamental properties and applications of UHMWPE is crucial. It's a step towards harnessing the full potential of this extraordinary material, whether you're seeking a UHMWPE sheet for your next project or exploring its various applications.

As we continue to explore and expand the applications of UHMWPE, it remains a testament to the incredible advancements in polymer science and engineering.

Ready to explore the possibilities with UHMWPE?

Purchase top-quality UHMWPE material from ePol, Australia's premier engineering plastics supplier. Enjoy live stock availability, free nationwide delivery on orders over $150, and hassle-free ordering.

Register online today and experience the ePol difference!